SGS Waste Water Treatment Line

- Payment Type:

- L/C, T/T, D/P

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Jiangsu Suzhou |

|---|---|

| Payment Type: | L/C, T/T, D/P |

Product Description

Product Description

1.Project Overview

1.1 Project overview

The factory is located in xxx,wastewater mainly comes from the following zones: xxx and xxx

Main adoptive wastewater treatment technology:

(1) Air Floatation

(2) Membrane Bioreactor (MBR)

(3) Reverse Osmosis (RO)

This System insures treated water standard, automatic PLC control, easy operation and maintenance.

1.2 Wastewater

1.2.1 Wastewater source:

(1) Degreasing wastewater is 15 m3 per month;

·degreasing tank; the main chemical component is sodium hydroxide, pH=9.0-11.0,volume is 900 liters,solution change is 4 times per month .solution temperature is 60 ºC.

·tap water rinsing tank -2pcs; volume is 900 liters each, solution change is 4 times per month, tank rinsing is 4 times per month, volume of rinsing water is 4000 liters per month.

(2) Iron series phosphating wastewater is 27 m3 per month .

·iron phosphating tank; the main chemical component is orthophosphoric acid( the agent is Granodine 1070,the manufacturer is "Henkel"), pH is 4.5-5.6, volume is 4000 liters, solution change is once per month ,tank rinsing is once per month ,volume of rinsing water is 8000 liters, solution temperature is 45-55ºC.

·tap water rinsing tank-1pc; volume is 2500 liters, water change is 4 times per month, tank rinsing is once per month, volume of rinsing water is 5000 liters.

2.Project Design

(2)Nature Conservation Act of Russian SFSR;

(3)Administrative Laws and Regulations of Barnaul NO.2557( August 30, 2010);

(4)other documents delivered by customer.

3. Process Flow

3.1 Process flow

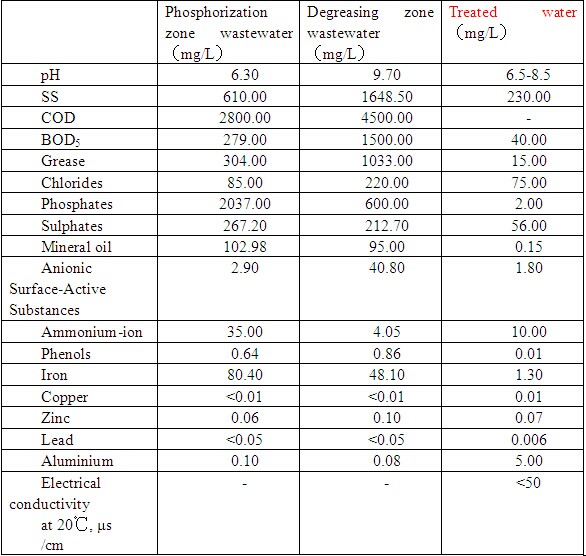

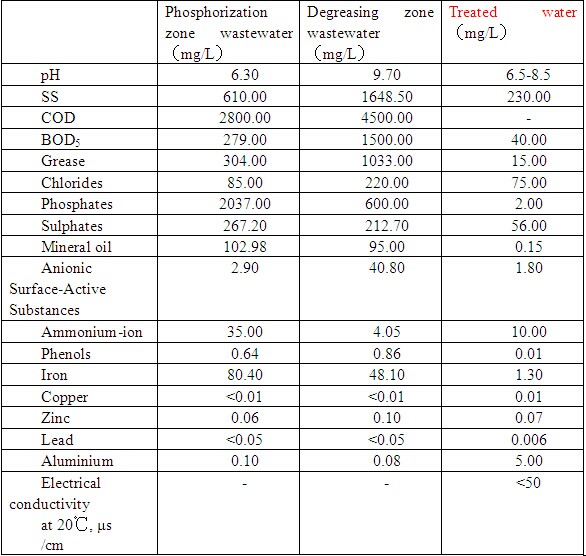

Based on the technological process in the 2 production zones and chemical analysis of wastewater, wastewater treatment process (WWTP) of Air Floatation combined with Membrane Bioreactor (MBR) and Reverse Osmosis (RO) is selected. The details of WWTP are shown as below:

4. Main Equipments Design

4.1 Cavitation Air Flotation

Everyday runs 40min design flow: 3 m3/h

size: 2.3 m * 0.8 m * 0.8 m quantity: 1 set

N = 1.6 kW material: corrosion carbon steel

Dosing system:

N = 0.8 kW material: PE quantity: 2 sets

4.2 Membrane Bioreactor (MBR)

Everyday inflows 1 h aeration runs 20 h

material: corrosion carbon steel design flow: 2 m3/d

Reactor:

size: 2.3 m * 1.0 m * 1.0 m material: corrosion carbon steel

total volume: 8 m3 containing internal aerator and membrane

Fan: Q = 0.94 m3/min quantity: 2 sets

P = 34.3 kPa N = 1.1 kW

Discharge pump: Q = 12 m3/h quantity: 2 sets

H = 8 m N = 0.75 kW

4.3 Reverse Osmosis (RO)

Everyday runs 2 h design flow: 1 m3/h frame materials: SUS304 N =5.5 kW

including pump, the precision filter and reverse osmosis membrane, etc

5. Public Engineering Design

5.1 Water supply and drainage and fire fighting

(1) According to the local laws and regulations of your country, design water supply and drainage facilities.

(2) According to the local laws and regulations of your country, design fire control system.

(3) According to the local laws and regulations of your country, design power system.

5.2 Architectural design basis

According to the local laws and regulations of your country, design related building .

1.1 Project overview

The factory is located in xxx,wastewater mainly comes from the following zones: xxx and xxx

Main adoptive wastewater treatment technology:

(1) Air Floatation

(2) Membrane Bioreactor (MBR)

(3) Reverse Osmosis (RO)

This System insures treated water standard, automatic PLC control, easy operation and maintenance.

1.2 Wastewater

1.2.1 Wastewater source:

(1) Degreasing wastewater is 15 m3 per month;

·degreasing tank; the main chemical component is sodium hydroxide, pH=9.0-11.0,volume is 900 liters,solution change is 4 times per month .solution temperature is 60 ºC.

·tap water rinsing tank -2pcs; volume is 900 liters each, solution change is 4 times per month, tank rinsing is 4 times per month, volume of rinsing water is 4000 liters per month.

(2) Iron series phosphating wastewater is 27 m3 per month .

·iron phosphating tank; the main chemical component is orthophosphoric acid( the agent is Granodine 1070,the manufacturer is "Henkel"), pH is 4.5-5.6, volume is 4000 liters, solution change is once per month ,tank rinsing is once per month ,volume of rinsing water is 8000 liters, solution temperature is 45-55ºC.

·tap water rinsing tank-1pc; volume is 2500 liters, water change is 4 times per month, tank rinsing is once per month, volume of rinsing water is 5000 liters.

2.Project Design

- Design basis

2.2 Design principle

(1)Environmental Protection Act(Russian)(January 10, 2002);(2)Nature Conservation Act of Russian SFSR;

(3)Administrative Laws and Regulations of Barnaul NO.2557( August 30, 2010);

(4)other documents delivered by customer.

3. Process Flow

3.1 Process flow

Based on the technological process in the 2 production zones and chemical analysis of wastewater, wastewater treatment process (WWTP) of Air Floatation combined with Membrane Bioreactor (MBR) and Reverse Osmosis (RO) is selected. The details of WWTP are shown as below:

4. Main Equipments Design

4.1 Cavitation Air Flotation

Everyday runs 40min design flow: 3 m3/h

size: 2.3 m * 0.8 m * 0.8 m quantity: 1 set

N = 1.6 kW material: corrosion carbon steel

Dosing system:

N = 0.8 kW material: PE quantity: 2 sets

4.2 Membrane Bioreactor (MBR)

Everyday inflows 1 h aeration runs 20 h

material: corrosion carbon steel design flow: 2 m3/d

Reactor:

size: 2.3 m * 1.0 m * 1.0 m material: corrosion carbon steel

total volume: 8 m3 containing internal aerator and membrane

Fan: Q = 0.94 m3/min quantity: 2 sets

P = 34.3 kPa N = 1.1 kW

Discharge pump: Q = 12 m3/h quantity: 2 sets

H = 8 m N = 0.75 kW

4.3 Reverse Osmosis (RO)

Everyday runs 2 h design flow: 1 m3/h frame materials: SUS304 N =5.5 kW

including pump, the precision filter and reverse osmosis membrane, etc

5. Public Engineering Design

5.1 Water supply and drainage and fire fighting

(1) According to the local laws and regulations of your country, design water supply and drainage facilities.

(2) According to the local laws and regulations of your country, design fire control system.

(3) According to the local laws and regulations of your country, design power system.

5.2 Architectural design basis

According to the local laws and regulations of your country, design related building .

Related Keywords

Related Keywords