PVC corrugated roofing tile machine for plastic tile

- Payment Type:

- T/T, L/C

- Incoterm:

- FOB

- Min. Order:

- 1 Set/Sets

- Min. Order:

- 1 Set/Sets

- Delivery Time:

- 75 Days

- Transportation:

- Ocean

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | china |

|---|---|

| Productivity: | 250kg |

| Supply Ability: | 100 Set/Sets per Month corrugated roofing tile machine |

| Payment Type: | T/T,L/C |

| Incoterm: | FOB |

| Certificate: | CE ISO9001 |

| Transportation: | Ocean |

|

Model SJZ65/132 SJZ80/156 |

|

Product width (mm) 840-1130 1130-1450 |

|

Product Thickness(mm) 0.8-3 0.8-3 |

|

Product Waveform circular/trapezoidal wave circular/trapezoidal wave |

|

Max. extrusion capacity(kg/h) 250 400 |

|

Extruder power(kw) 37 55 |

Product Feature:

PVC corrugated roof tile has a character in noise reduction, heat insulation and acid and alkali corrosion resistance, colorful; it can instead of color steel plate. Corrosion resistance, aging resistance, long service life (> 25 years)

Product Specification:

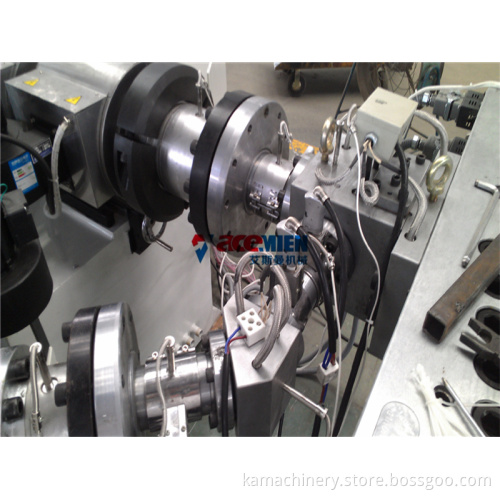

PVC corrugated roof tile extrusion line consists of:

1) Extruder: adopts conical twin-screw, it is designed specially to for PVC material.

8) Haul-off unit: it is of simple two-roller take-up design, clearance can be freely adjusted, and it adopts frequency conversion speed control, which ensures various extrusion speed and stable running.

9) Cutting unit: feasible cutting style, the super alloy steel blade ensures quick and smooth cutting.

2) Screw barrel: guarantee excellent plasticizing effect for all kinds of formula. The screw is equipped with internal temp. Controlling device as well as good cooling system for barrel, this assures precise temp.control for material during processing. Guarantee good quality of product with vacuum degassing device,which can get rid of moisture and waste gas from material.

3) Gear box: high torque transmission system, the gear and shaft are made of super alloy steel, which can meet the requirements of high torque, low noise, stable running.

4) Barrel cooling: it has good cooling effect with high quality ceramic heater.

5) Extruding die: the advanced design of multi-channel assure the plastic flow coming out from the wide die lip, the clearance of die lip can be freely adjustable.

6) Heating unit: it applies performing treatment to meet forming requirement before coming to second processing.

7) Forming unit: its suitable design ensures quick forming, exact size of sheet...

10) Control system: variety of control system available for different customer`s requirement. (Such as PLC control)

Related Keywords