Demountable Prefab Modified Shipping Containers Home With E

- Min. Order:

- 1

- Min. Order:

- 1

- Delivery Time:

- 30 Days

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Yangzhou,Jiangsu,China |

|---|

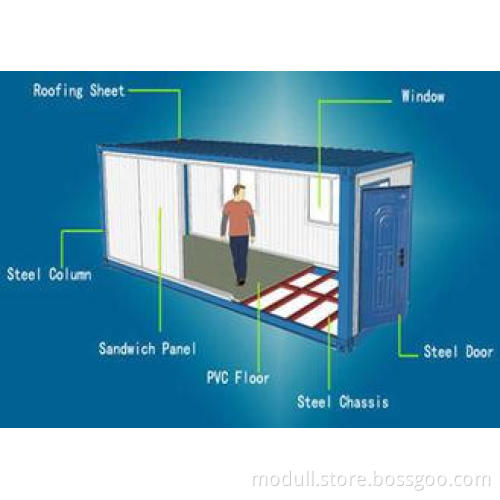

Demountable Prefab Modified Shipping Containers House With EPS Sandwich Panel Wall

Application

Flat-packed container house is one of our popular products. It is widely used for office, accommodation, hotel, hospital, commercial kiosk, parlor, bedroom, study room, locker room, ablution room, school, shower room, kitchen, dining room, works camp, exhibition, dormitory, villa, carport, house, coffee room, booth, sentry box, guard house, shop, toilet, warehouse, workshop, plant and so on.

Description

This product is on the basic of 20 feet container. With the modern design and advanced technical skills which made itelegant and comfortable. It has a good insulation which was made by Neopor (It is made in Germany BSF). The strong firm structure was made by galvanized steel frame, so the life time will be more than 30-50 years.

Specification

Dimension(mm)&Weight(kg)

|

Type |

External |

Internal |

Weight (kg) |

|||||

|

Length |

Width |

Height (package) |

Height (assembled) |

Length |

Width |

Height |

||

|

20’ |

6055 |

2435 |

648/864 |

2591/2790 |

5860 |

2240 |

2500 |

from 1850 |

Floor

|

Steel frame |

- made from cold rolled, welded steel profiles, 4 mm thick |

|

- 4 corner casts, welded |

|

|

- 2 fork lift pockets (except 30’) - distance 1200mm (internal clearance of fork lift pockets: 240×80 mm) |

|

|

- steel cross members, thickness=2mm |

|

|

Insulation |

- 100 mm thick Rock Wool |

|

Subfloor |

- 0.5mm thick, galvanized steel sheet |

|

Floor |

- 18mm plywood board |

|

- 1.8mm PVC floor - flammability class B1 - hardly combustible - smoke density class Q1 - low smoke emission - wear resistance factor: T level |

Roof

|

Steel frame |

- made from cold rolled, welded steel profiles, 3mm thick |

|

- 4 corner casts, welded |

|

|

- steel cross members, thickness=2mm |

|

|

Roof cover |

- 0.5mm thick, galvanized steel sheet - 360 degree seaming at joint of roof panels |

|

Insulation |

- 100 mm thick Rock Wool |

|

Ceiling |

- 10 mm chipboard (V 20), laminated on both sides, white - the chipboard complies with the emission value E1 |

|

CEE connector |

- sunken in frame on short end side |

Insulation

|

Rockwool |

- density:120kg/m3 |

|

- flammability class A- non combustible - smoke density class Q1 - low smoke emission |

|

|

- certificated: CE & GL |

|

|

NeoporR |

- density:18kg/m3 |

|

- flammability class B1- non combustible - smoke density class Q1 - low smoke emission |

|

|

- certificated: CE & GL |

Coatings (Optional)

|

DecoCoating |

Special coating can be applied on top of sandwich wall panel and make the external wall surface looks like plastering finishes or timber finishes. That makes the container house cozy and less industry look. |

Competitive Advantage

|

1 |

Strong Structure

|

All parts are galvanized, lifetime more than 30 years. Can be stacked up to 3 floors. |

|

2 |

Modular Design

|

They are able to stack each other and fixed through high tensile screws. |

|

3 |

Factory Quick Respond

|

Modular design minimized and standardized part. That makes quick combination and respond possible. |

|

4 |

Minimized Site Work |

The assembly only requests simple tools. That helps to save equipment cost and labor cost. No cast-in-situ concrete slab is needed. The original floor such as turf will not be damaged.

|