Hospital Shredder

- Payment Type:

- L/C, T/T, Western Union

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Jiangshu |

|---|---|

| Payment Type: | L/C, T/T, Western Union |

Product Description

Product Description

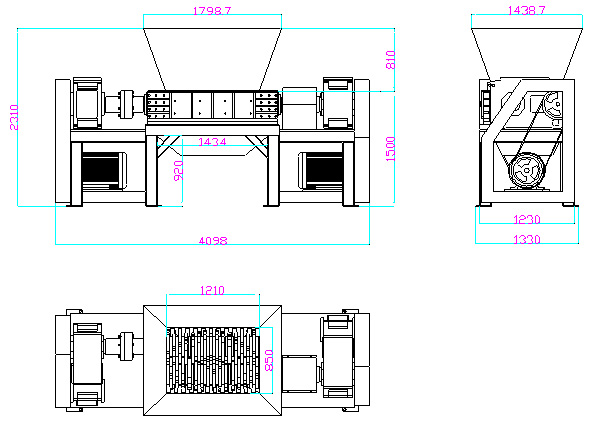

Drawing of machine

Knife photo

Knife photo

Specification

D1250 has the advantages of high efficiency, high torque, low noise.

1, The crusher body

The main body of the device Q235 steel plate welded to stress relief processing /

overall machining, to ensure the stability of the device in the long heavy-duty.

2, Knife / fixed blade

Knife materials using special alloy tool steel, forged blanks, precision machining, multiple heat treatment and cryogenic heat treatment technology from the overall toughness, hardness consistent repeat repair use, ensure that the cutting performance and service life. Fixed knife with patented hook installation, optimization tool change function, the tool more efficient maintenance or replacement.

3, The bearing / seal

Bearing seat using patented split will be demolished, can quickly remove the knife, fixed blade, bearings and other components, easy to maintain and replace the tool, unique seal structure effectively blocking the contact of broken material and grease, the handling of liquid material can protect the bearing and gear.

4, the Shaft

High-strength the heavy special steel processing refined, more reasonable with the tool to provide a strong impetus for cutting.

5, Rack hopper

Can be used with the customers' premises personalized customized processing, more integrated into the production line for large-scale production.

6, High-performance motor reducer:

The domestic brands of energy efficiency standard motor, excellent standard export loaded, and load testing at the factory to ensure the stability of the power system.

7, The electrical control system:

The main electrical control brand electrical components and Siemens / Mitsubishi PLC intelligent control system, access to materials conveyor contacts in the electric box control, simple operation and safety.

8, Multiple protection system:

Broken system with mechanical and electrical multiple intelligent protection, a main motor starters protection, automatic relax feeding to prevent overload, the motor stuck overload, auto-reverse re-cloth materials to be crushed protection (reversals adjustable).

Noise reduction and dust reduction measures are taken into account in the design process, to minimize noise and dust of the efflux: Device operating point noise ≤ 85dB.

Related Keywords

Related Keywords