Full Auto Spiral Tube Forming Machine with CE

- Payment Type:

- T/T, Money Gram, Western Union

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Jiangsu China(Mainland) |

|---|---|

| Payment Type: | T/T, Money Gram, Western Union |

Product Description

Product Description

Full Auto Spiral Tube Forming Machine with CE

Usage and Feature:

Our latest patent and the most advanced Spiral Tubeformer Machine, which can make tube & pipe up to 2500mm, material thickness up to 2mm. It's the most idealist spiral duct machine to making tube, pipe, duct etc.

- Fully auto material feeding, forming, lubrication, cutting, tube loading

-Built with Mitsubishi PLC control panel and transducer, speed could be adjusted.

-With lubrication system, could lubricate automatically.

-Tension controlled by air pressure, auto brake.

-With air and hydraulic pressure system, save power.

-According to European standard, speed adjusted by pneumatic brake, which

Could be unanimous & synchronous

With auto counting system and photoelectric tracking, pipe quantity could be counted.

-Different mould to meeting respective request, just change mould to

make various diameter.

-Complete with meter cutting length control, meter could be controlled and

- Calculated; when reach set meter, could slit automatically.

- Combination of both Western & Asian Technologies on complete production and control.

-Complete with all safety features, auto alarm and urgent stop.

Main Technical Specification:

-Finished Product Diameter 80 - 2500mm

-Max.Unwinding Diameter 1200mm

-Max.Unwinding Roller Loading 3000kg(3 rolls)

-Material Thickness 0.4 -2mm (Galvanized steel)

0.4-1.2mm (Stainless steel)

0.4-2.0mm (Aluminum)

-Max.Material Width 140mm

-Cutting way flying slitter

-Lock Way Outer (inner also available)

-Max.Speed 65m/min

-Power 33kw

-Voltage 380V/50Hz (three phase)

-Weight 2950kg

-Machine dimension (LxWxH) 3000mm*1950mm*1710mm.

Finished Products:

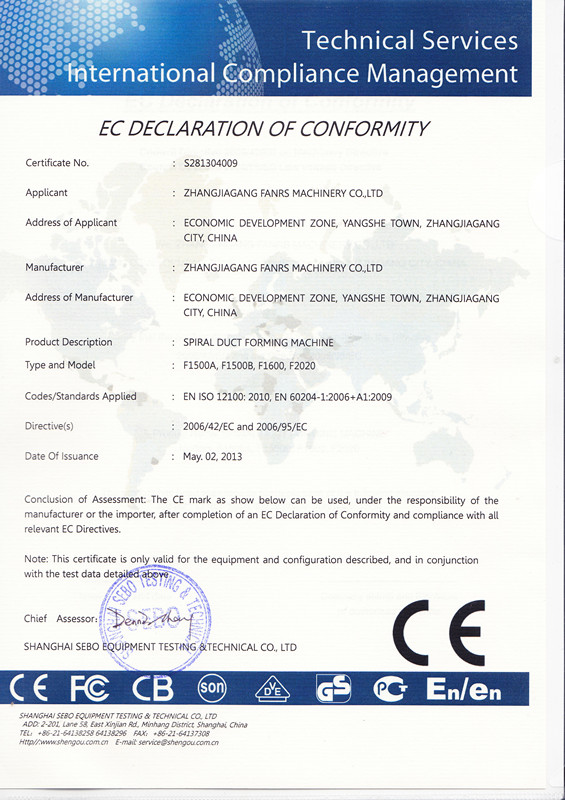

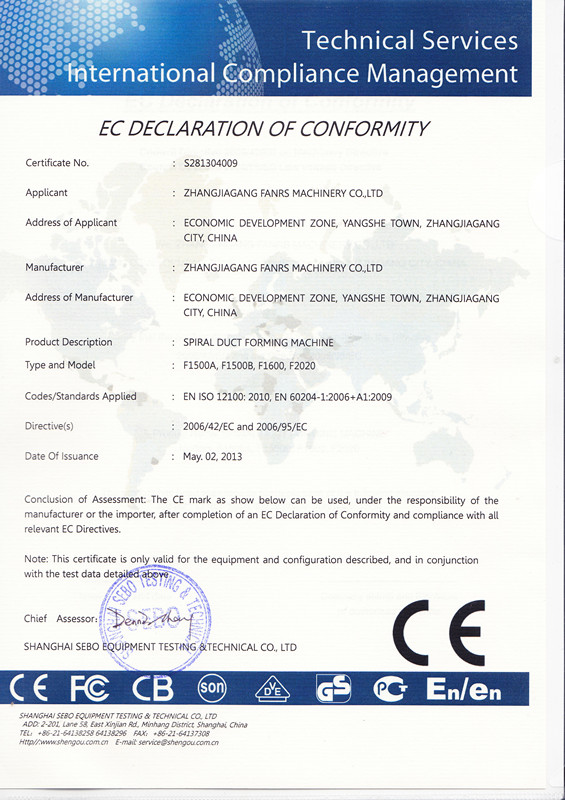

CE Certificate:

Contact Data:

Our latest patent and the most advanced Spiral Tubeformer Machine, which can make tube & pipe up to 2500mm, material thickness up to 2mm. It's the most idealist spiral duct machine to making tube, pipe, duct etc.

- Fully auto material feeding, forming, lubrication, cutting, tube loading

-Built with Mitsubishi PLC control panel and transducer, speed could be adjusted.

-With lubrication system, could lubricate automatically.

-Tension controlled by air pressure, auto brake.

-With air and hydraulic pressure system, save power.

-According to European standard, speed adjusted by pneumatic brake, which

Could be unanimous & synchronous

With auto counting system and photoelectric tracking, pipe quantity could be counted.

-Different mould to meeting respective request, just change mould to

make various diameter.

-Complete with meter cutting length control, meter could be controlled and

- Calculated; when reach set meter, could slit automatically.

- Combination of both Western & Asian Technologies on complete production and control.

-Complete with all safety features, auto alarm and urgent stop.

Main Technical Specification:

-Finished Product Diameter 80 - 2500mm

-Max.Unwinding Diameter 1200mm

-Max.Unwinding Roller Loading 3000kg(3 rolls)

-Material Thickness 0.4 -2mm (Galvanized steel)

0.4-1.2mm (Stainless steel)

0.4-2.0mm (Aluminum)

-Max.Material Width 140mm

-Cutting way flying slitter

-Lock Way Outer (inner also available)

-Max.Speed 65m/min

-Power 33kw

-Voltage 380V/50Hz (three phase)

-Weight 2950kg

-Machine dimension (LxWxH) 3000mm*1950mm*1710mm.

Finished Products:

CE Certificate:

Contact Data:

ZHANGJIAGANG FANRS MACHINERY CO., LTD

TEL: +86-512 58905956

FAX: +86-512 58905957

MOB: +86 13301566940 (24 hours online)

FAX: +86-512 58905957

MOB: +86 13301566940 (24 hours online)

Web://www.fanrsmachinery.com

Related Keywords

Related Keywords