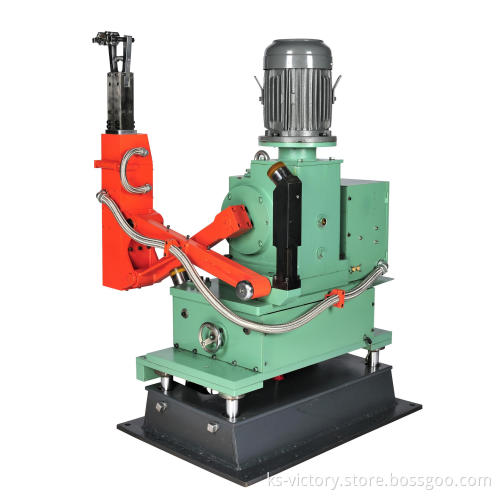

Extractor (WTE-C2#)

- Payment Type:

- L/C, T/T, D/P

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Changzhou, China |

|---|---|

| Payment Type: | L/C, T/T, D/P |

Product Description

Product Description

1. Motor worm and gear driving method is adopted in this model. The linkage mechanism is used to implement the function of extracting. This machine features simple structure, fast speed, stable operation, high efficiency and low service rate.

2. Brake-free motor and worm and gear reduction box is used to assure more stable and quicker operation, shorten production cycle, improve production efficiency and extend service life.

3. Imported electrical elements are adopted as the elements used in the main parts. Touch screen is adopted as the operation panel. All parameters of the machine (arm forward, backward, standby position, etc. ) may be modified, set and adjusted on the screen. It is quick, convenient and practicable.

4. The adjustment of this model is very convenient. The upward and downward adjustment will be realized by the jack at the bottom. The adjustment at the directions of axis X and axis Y is realized by the rotation of hand wheel. It is easy and convenient to replace and adjust shot position.

5. The Japan absolute value encoder is used to digitize the arm position adjustment. Double-layer shield network protection is applied outside the coil. It features strong interference resistance and moderate and stable pulse input and output to realize precise positioning of the machine.

6. To assure the integrity of parts extracted, double-pipe extracting detection mechanism is especially designed. The detection institution composed of two detection sensors can precisely detect the integrity of parts extracted from moulds. The 2 sensors can be combined at will in the work according to the shape of the workpiece (at most 16 detection points can be achieved according to the product structure as demanded). When the workpiece is not extracted or the extracting work is incomplete, automatic alarm will be triggered to remind to take out the residual parts manually before continuing the work. It has effectively assured unnecessary damages to the moulds.

7. Material handle with certain conical degree is clamped. Two chucks at upper and lower parts are installed at an angle of 90°. During clamping of material handle, the force is undertaken at four directions to improve the clamping stability. The clamping pressure can be controlled within the range of 4.5-5kgf/cm². It shall not be too high, thus influencing the service life of clamping jaw.

8. This machine is equipped with 1 automatic lubrication device. It is distributed by general oil pump to each sliding part to assure normal use of the machine.

2. Brake-free motor and worm and gear reduction box is used to assure more stable and quicker operation, shorten production cycle, improve production efficiency and extend service life.

3. Imported electrical elements are adopted as the elements used in the main parts. Touch screen is adopted as the operation panel. All parameters of the machine (arm forward, backward, standby position, etc. ) may be modified, set and adjusted on the screen. It is quick, convenient and practicable.

4. The adjustment of this model is very convenient. The upward and downward adjustment will be realized by the jack at the bottom. The adjustment at the directions of axis X and axis Y is realized by the rotation of hand wheel. It is easy and convenient to replace and adjust shot position.

5. The Japan absolute value encoder is used to digitize the arm position adjustment. Double-layer shield network protection is applied outside the coil. It features strong interference resistance and moderate and stable pulse input and output to realize precise positioning of the machine.

6. To assure the integrity of parts extracted, double-pipe extracting detection mechanism is especially designed. The detection institution composed of two detection sensors can precisely detect the integrity of parts extracted from moulds. The 2 sensors can be combined at will in the work according to the shape of the workpiece (at most 16 detection points can be achieved according to the product structure as demanded). When the workpiece is not extracted or the extracting work is incomplete, automatic alarm will be triggered to remind to take out the residual parts manually before continuing the work. It has effectively assured unnecessary damages to the moulds.

7. Material handle with certain conical degree is clamped. Two chucks at upper and lower parts are installed at an angle of 90°. During clamping of material handle, the force is undertaken at four directions to improve the clamping stability. The clamping pressure can be controlled within the range of 4.5-5kgf/cm². It shall not be too high, thus influencing the service life of clamping jaw.

8. This machine is equipped with 1 automatic lubrication device. It is distributed by general oil pump to each sliding part to assure normal use of the machine.

Related Keywords

Related Keywords