CE Webbing Canvas Fabric Foam Styrofoam Heat Cutter

- Payment Type:

- L/C, T/T, D/P, Paypal, Money Gram, Western Union

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Suzhou, China |

|---|---|

| Payment Type: | L/C, T/T, D/P, Paypal, Money Gram, Western Union |

CE Webbing Canvas Fabric Foam Styrofoam Heat Cutter

1. What is a Hot Knife?

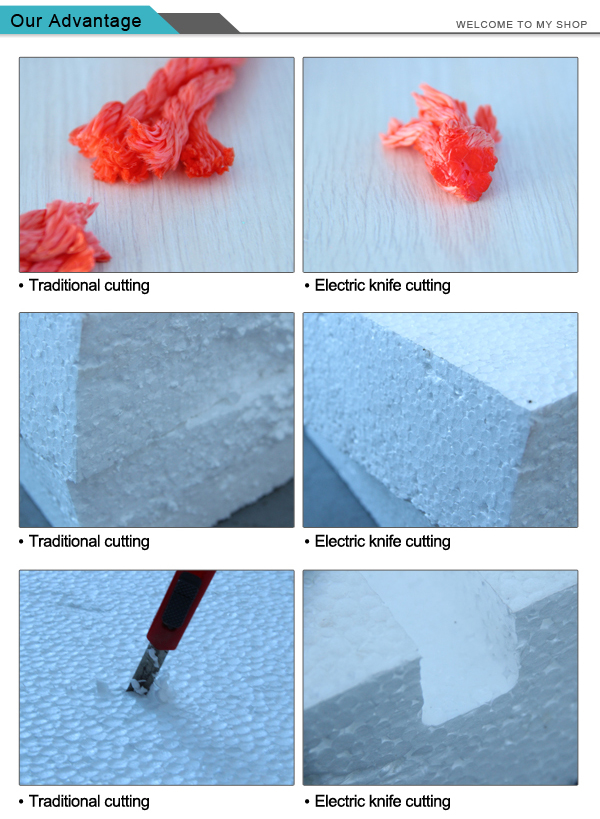

The Hot Knife is a professional-grade hot cutting tool for foamed plastics. The Hot Knife heats up in seconds and gives the operator temperature control. Never before has working with foamed plastics been this easy, inexpensive and free of mess.

A hot knife is normally a hand-held tool with a handle and heated blade. Most hot knives are

designed for cutting EPS foam (Styrofoam), or a similar type of insulating foam.

2. What can it do?

The foam cutter/grooving cutter is fpr cutting different density foam, with fine cutting edge, no mess.

Cutting with the groover-sled, it is easy to make different groove shape on the foam.

Cut the rope and the webbing, with fine cutting edge, no disperse. Attached with the cutting foot, the hot knife cut thre synthetic fiber cloth without backup under the cloth, seal the cutting edge as well; cut the seal line on the bag. Especially good for cutting sail cloth, awnings and filter cloth.

3. For the best results, practice on scrap pieces of foam.

A. Preparation

1. Select a hot knife blade corresponding to the cutting use.

2. Loosen the knurled nut when device is cold.

3. Insert each leg of the blade and tighten the knurled nuts. Make sure that the blade and the cutting head have optimal contact. If both legs of the blade are not properly installed, the unit will not heat up.

B. Cutting

1. Actuate switch, the indicator light and the blade will heat up.

2. Avoid direct short circuit between cutting heads.

3. Do not use metallic rulers for guiding the blade.

4. Clean cutting heads with enclosed wire brush.

5. Please make sure the blade is connected to the cutting material before blade heats up.

C. Caution

1. Always operate the Hot Knife in well ventilated space.

2. Never burn off the excess residue on the Hot Knife blade. The blades will over heated and be warped.

3. Only operate Hot Knife when it is in contact with the insulation board

4. Keep hot blades away from skin, clothing and other flammable materials.

5. Allow blades to cool before handling. Hot Knife may cause injury or burns to exposed surfaces.

6. If the temperature inside the tool is too high, the unit will get hot and the internal thermal protectors will turn it off, after it cool, the Hot Knife will operate again.

4. RFQ

Q. Are the cutting blades sharp?

A. No, the heat is what cuts the material, not the sharpness of the blade you're using.

Q. How should I clean off my cutting blade?

A. The simplest way is to get the blade nice and hot and clean the blade off with a brush. This will extend the life of blade.

Q. Can your equipment seal two pieces of material together?

A. We specialize in heat cutting one layer of synthetic material at a time and as you cut the material it will seal the edge so that it doesn't fray. When two or more pieces of synthetic material are on top of each other and are being cut with our heat cutters, they will seal together, but there is no guarantee how strong the seal is bonded together.

Q. Does your equipment come with a warranty?

A. Yes, our equipment comes with a one-year manufacturer's warranty that starts from the date of the original retail purchase and it covers any and all manufacturers' defects. This warranty does not cover any product that has been altered, modified or damaged, neglected, accidently dropped or improperly used.

Q. How long do the blades normally last?

A. The blades last around 3 to 6 months if they are being used correctly. Keeping the blade clean by using a brush while it's heated, it will extend the life of blade.

Q. Do you sell voltage converters?

A. Yes, we can special order you a voltage converter, whether convert 110V to 220V or 220V to 110V.

Related Keywords