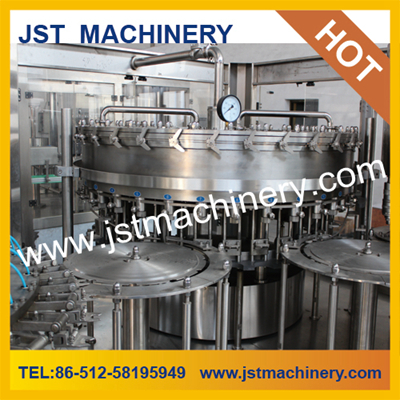

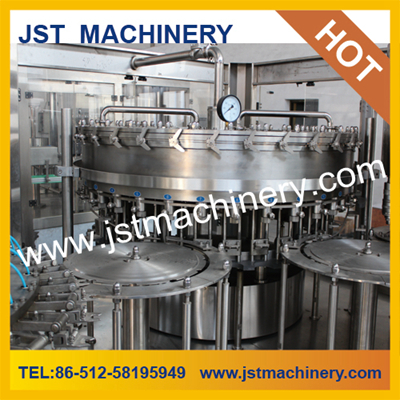

Pet Bottle Automatic Carbonated Gas Drink Filling Line

- Payment Type:

- L/C, T/T, Paypal, Western Union

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Zhangjiagang City, Jiangsu Province, China |

|---|---|

| Payment Type: | L/C, T/T, Paypal, Western Union |

Product Description

Product Description

PET bottle automatic carbonated gas drink filling line

Description:

1. carbonated drink filling line

2. Glass bottle filling line/PET bottle filling line/Plastic bottle filling line

3. Suitble bottle: Plastic bottle/PET bottle 250ml-2000ml

4. Filling type: Three in one bottling plant DCGF18-18-6

5. Filling speed: 5000@ 500ml

This carbonated drink filling line carries out washing, filling, cappingas three in one machine. The whole machine designing is reasonable. The appearance is beautiful and maintenance is convenient. It adopts bottle handing thchnology to make changing bottle more convenient, faster and easier from jst company. The main machine adopts advanced PLC control, Touch screen and no- bottle, no-cap system. The key electirc elements are from famous international brand.

Main complete automatic aerated beverage filling line components:

1) driving system;

2) bottle-loading system;

3) bottle-rinsing system;

4) handing-over system between rinsing and filling;

5) filling system;

6) handing-over system between filling and capping;

7) capping system;

8) cap-unscrambling system;

9) bottle-unloading system;

10) frame;

11) electrical system.

Soft drinks bottling line ----rinser

Spring cramps are used in the bottle washing process. The empty bottles can be turned over 180° Along the conveying rail. There are two times of internal and external washing, the efficiency of bottle washing is high.

Rinsing machine adopts JST original overturn and double-opened bottle clip. Bottle clip lock the bottleneck, the material of bottle clip is SUS304, which is hygienic and durable.

Bottle clip equipped with efficient spray on nozzle. The extrusive droplet with 15° Angleensures to wash all side of the bottle, and can save the water.

carbonate bottling line---- filler

Designed of filling structure is reasonable and hygiene dead angle, the run of equipment is stable, it can control the material from the bottleneck, the control accuracy is within ± 2mm (subject to bottle design). The jst company filling valve material is SUS304. The filling system has liquid level automatic control. Filling valve lift is controlled by the valve elevator, after filling valve contact the bottleneck, it starts to fill. Bottle is conveying by the wheel in the filling part.

Gas drinks bottling line ---capper

Screw capping machine is most precision part in the 3-in-1 machine, it has a big influence to the goods stability and defective rate. JST company screw capping has following feature.

1)JST import of advanced technology of screw capping, improve the stability and reliability of the screw capping machine. The magnetic torque is used for screw capping. Thepower of screw capping can be adjusted without steps. The power of the screw capping can also be fixed, and the caps will not be damaged, the capping is reliable.

2) In the screw capping part. It installed photoelectrical control, when it has no cap, or the cap is bad, the machine will stop automatically.

After-sales service for gas drink filling line PET bottled:

We will send one professional engineer to install the whole line for you, but you should pay him USD 60 / DAY as salary, also include his return tickets, room, food and visa fee.

Machine guarantee time: 12 months

FAQ for filling line

1. What kind of products will you produce?

2. What is the capacity(per hour) you want?

3. What kind of package, plastic bottle, glass bottle: Volume, height, neck diameter, diameter of bottle or other please inform us of details.

4. Sole machine or whole production line?

Description:

1. carbonated drink filling line

2. Glass bottle filling line/PET bottle filling line/Plastic bottle filling line

3. Suitble bottle: Plastic bottle/PET bottle 250ml-2000ml

4. Filling type: Three in one bottling plant DCGF18-18-6

5. Filling speed: 5000@ 500ml

This carbonated drink filling line carries out washing, filling, cappingas three in one machine. The whole machine designing is reasonable. The appearance is beautiful and maintenance is convenient. It adopts bottle handing thchnology to make changing bottle more convenient, faster and easier from jst company. The main machine adopts advanced PLC control, Touch screen and no- bottle, no-cap system. The key electirc elements are from famous international brand.

Main complete automatic aerated beverage filling line components:

1) driving system;

2) bottle-loading system;

3) bottle-rinsing system;

4) handing-over system between rinsing and filling;

5) filling system;

6) handing-over system between filling and capping;

7) capping system;

8) cap-unscrambling system;

9) bottle-unloading system;

10) frame;

11) electrical system.

Soft drinks bottling line ----rinser

Spring cramps are used in the bottle washing process. The empty bottles can be turned over 180° Along the conveying rail. There are two times of internal and external washing, the efficiency of bottle washing is high.

Rinsing machine adopts JST original overturn and double-opened bottle clip. Bottle clip lock the bottleneck, the material of bottle clip is SUS304, which is hygienic and durable.

Bottle clip equipped with efficient spray on nozzle. The extrusive droplet with 15° Angleensures to wash all side of the bottle, and can save the water.

carbonate bottling line---- filler

Designed of filling structure is reasonable and hygiene dead angle, the run of equipment is stable, it can control the material from the bottleneck, the control accuracy is within ± 2mm (subject to bottle design). The jst company filling valve material is SUS304. The filling system has liquid level automatic control. Filling valve lift is controlled by the valve elevator, after filling valve contact the bottleneck, it starts to fill. Bottle is conveying by the wheel in the filling part.

Gas drinks bottling line ---capper

Screw capping machine is most precision part in the 3-in-1 machine, it has a big influence to the goods stability and defective rate. JST company screw capping has following feature.

1)JST import of advanced technology of screw capping, improve the stability and reliability of the screw capping machine. The magnetic torque is used for screw capping. Thepower of screw capping can be adjusted without steps. The power of the screw capping can also be fixed, and the caps will not be damaged, the capping is reliable.

2) In the screw capping part. It installed photoelectrical control, when it has no cap, or the cap is bad, the machine will stop automatically.

After-sales service for gas drink filling line PET bottled:

We will send one professional engineer to install the whole line for you, but you should pay him USD 60 / DAY as salary, also include his return tickets, room, food and visa fee.

Machine guarantee time: 12 months

FAQ for filling line

1. What kind of products will you produce?

2. What is the capacity(per hour) you want?

3. What kind of package, plastic bottle, glass bottle: Volume, height, neck diameter, diameter of bottle or other please inform us of details.

4. Sole machine or whole production line?

Related Keywords

Related Keywords

You May Also Like

You May Also Like