Automatic 2000bph Pop Can Carbonated Soft Drink Filling Machine

- Payment Type:

- L/C, T/T, Western Union

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | Zhangjiagang City, Jiangsu Province, China |

|---|---|

| Payment Type: | L/C, T/T, Western Union |

1. This equipment is used for filling carbonated beverage in cans , such as beer, cola, energy drinks and soda water.

2. This equipment can be used for different material of cans, such as plastic, iron, aluminum and so on ,and the different size of cans is allowed.We can design the euipment according to your requirements

3. It is applicable for equal pressure filler and capper of carbonated drinks in beer and drink industry.

4. It is a pop can carbonated soft drink in the digestion and absorption of advanced foreign and domestic sealing machine on the basis of independent development of the can filling, sealing unit.

5. Filling and sealing is the overall designed, power system by filling sealing system to Ensure that both the absolute synchronization and coordination.

6. It adopts the advanced machine, electrical equipment, and Pneumatic control technology.

7. It has the characteristics of filling reposefully, high speed, liquid level control, capping reliably, frequency conversion timing, less material loss.

8. It can equip long-distance control system according to the Customers request.

9. It is the preferred equipment for the medium beer and beverage plant.

Top can filling machine detail photos :

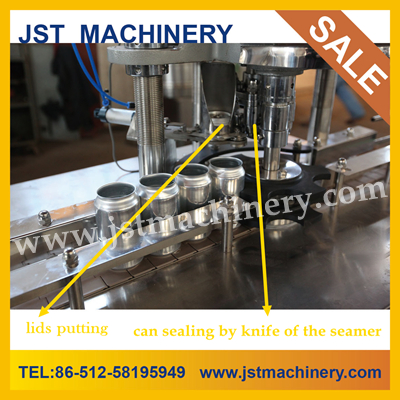

Aluminium can sealing machine detail photo :

Machine package photos for easy open can drink filling machines :

After-sales service for can beverage filling machine :

We will send one professional engineer to install the whole line for you, but you should pay him USD 60 / DAY as salary, also include his return tickets, room, food and visa fee.

Machine guarantee time: 12 months

FAQ for easy open can filling machine :

1. What kind of products will you produce?

2. What is the capacity(per hour) you want?

3. What kind of package, plastic bottle, glass bottle: Volume, height, neck diameter, diameter of bottle or other please inform us of details.

4. Sole machine or whole production line?

Related Keywords