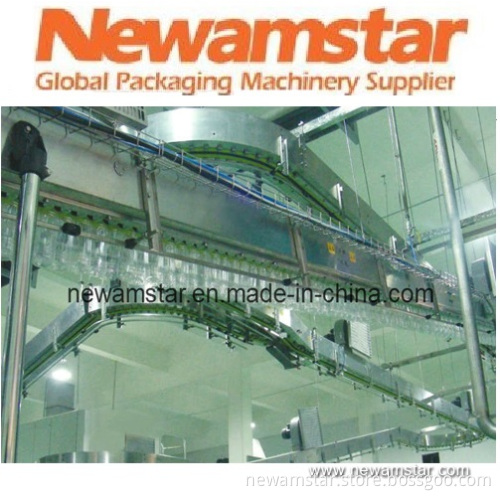

Air Conveyor System

- Payment Type:

- L/C, T/T

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | China |

|---|---|

| Payment Type: | L/C, T/T |

Product Description

Product Description

Specifications

Air Conveyor System

1. Certificate: CE, SGS, ISO

2. Material: ANSI304

Air Conveyor System

Air channel uses stainless steel SUS304 and holding rail adopts imported HDPE macromolecule material, featuring bottle stability, non-jam, non-lock, etc.

HEPA filter is installed on fan inlet, avoiding dust blowing into bottles.

According to clients requirement, it can be upgrade as aseptic conveying.

General Description

Air conveyor is fixed on the floor, with fan installed on the top. Air filter is positioned at every entrance of air fan, to prevent dust blown into bottles. Bottles are held on the neck in the conveyor and transported into filling machine by blowing power. All are made of stainless steel SUS304, except the horses with plastic and nylon.

Main Features

1) All are made of stainless steel SUS304, except some parts as plastic and nylon made horses and supporting carrier plate.

2) Air filter is installed in the door of every fan, to avoid dust blown into bottles.

3) Bottle infeed port is equipped with bottle-block elimination device driven by hydraulic cylinder, which will remove blocked bottles automatically to prevent damage of bottle blow molding machine.

Technical Parameters

1) )Quantity of fans: One in every 6 meters

3) Power of fan: 2.2KW/Unit

4) Length of air conveyor: According to plant layout

Air Conveyor System

1. Certificate: CE, SGS, ISO

2. Material: ANSI304

Air Conveyor System

Air channel uses stainless steel SUS304 and holding rail adopts imported HDPE macromolecule material, featuring bottle stability, non-jam, non-lock, etc.

HEPA filter is installed on fan inlet, avoiding dust blowing into bottles.

According to clients requirement, it can be upgrade as aseptic conveying.

General Description

Air conveyor is fixed on the floor, with fan installed on the top. Air filter is positioned at every entrance of air fan, to prevent dust blown into bottles. Bottles are held on the neck in the conveyor and transported into filling machine by blowing power. All are made of stainless steel SUS304, except the horses with plastic and nylon.

Main Features

1) All are made of stainless steel SUS304, except some parts as plastic and nylon made horses and supporting carrier plate.

2) Air filter is installed in the door of every fan, to avoid dust blown into bottles.

3) Bottle infeed port is equipped with bottle-block elimination device driven by hydraulic cylinder, which will remove blocked bottles automatically to prevent damage of bottle blow molding machine.

Technical Parameters

1) )Quantity of fans: One in every 6 meters

3) Power of fan: 2.2KW/Unit

4) Length of air conveyor: According to plant layout

Related Keywords

Related Keywords