Air Conveyor Fdss

- Payment Type:

- L/C, T/T

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | China |

|---|---|

| Payment Type: | L/C, T/T |

Product Description

Product Description

General description

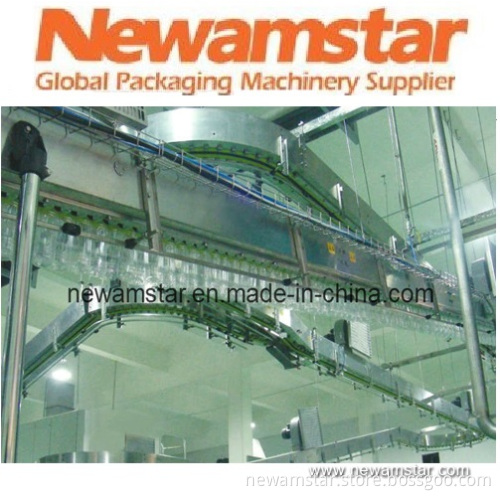

Air conveyor is the main transport device of PET bottling line. Its function is connecting PET bottle blowing machine or loading equipment with filler, transporting bottles by air.

The main body of air conveyor is made of stainless steel. The air slot of air conveyor is made by punch. The air slot equips polymer leading bars. Adjusting the gap between leading bars makes PET bottle hang on the bars naturally. There are fans on the top of the air conveyor. The inlet of the fan equips air filtering device which can block dust effectively. While the fan starts, air exhausts from the outlet and directly blows to bottle mouth and body to make bottles have pressure. Under effect of pressure, bottles are transported fast along the designed line.

Features

Modularization design makes product varying and simple, with strong interchangeability. The consecutive joint can satisfy long-distance transport.

The outlet of the fan equips air adjust device. For different bottles, air quantity can be adjusted to keep stable transport.

The leading bar is made of polymers, reducing the friction to bottles and ensuring smooth transport.

Adopt polymers leading bar to protect bottle body, reducing the scoring to bottle body.

Special air slot design made by punch ensures the coherence of each unit and smooth transport.

It considers the requirement of sanitary and cleanness for bottle inside. The inlet of the fan adopts air filtering device made of non-woven fabrics cotton, with high filtering class, easy to change filter gauze.

Newamstar Packaging Machinery Co., Ltd.

Air conveyor is the main transport device of PET bottling line. Its function is connecting PET bottle blowing machine or loading equipment with filler, transporting bottles by air.

The main body of air conveyor is made of stainless steel. The air slot of air conveyor is made by punch. The air slot equips polymer leading bars. Adjusting the gap between leading bars makes PET bottle hang on the bars naturally. There are fans on the top of the air conveyor. The inlet of the fan equips air filtering device which can block dust effectively. While the fan starts, air exhausts from the outlet and directly blows to bottle mouth and body to make bottles have pressure. Under effect of pressure, bottles are transported fast along the designed line.

Features

Modularization design makes product varying and simple, with strong interchangeability. The consecutive joint can satisfy long-distance transport.

The outlet of the fan equips air adjust device. For different bottles, air quantity can be adjusted to keep stable transport.

The leading bar is made of polymers, reducing the friction to bottles and ensuring smooth transport.

Adopt polymers leading bar to protect bottle body, reducing the scoring to bottle body.

Special air slot design made by punch ensures the coherence of each unit and smooth transport.

It considers the requirement of sanitary and cleanness for bottle inside. The inlet of the fan adopts air filtering device made of non-woven fabrics cotton, with high filtering class, easy to change filter gauze.

Newamstar Packaging Machinery Co., Ltd.

| Model: FDSS(K) | Side sign: FDSS(K)-00 | |||

| Description | Spec.or parameter | unit | ||

| Applicable bottle neck: | Ø20-40 | mm | ||

| Section size(L×W): | 250×230 | mm | ||

| Elbow radius: | 800 | 1000 | mm | |

| Fan power : | 2.2 | 3 | Kw | |

| Effective unit transport distance: | 6000 | 8000 | mm | |

| Applicable gradient | 0-15° | |||

| Filtering class | ≥G4 | |||

Related Keywords

Related Keywords