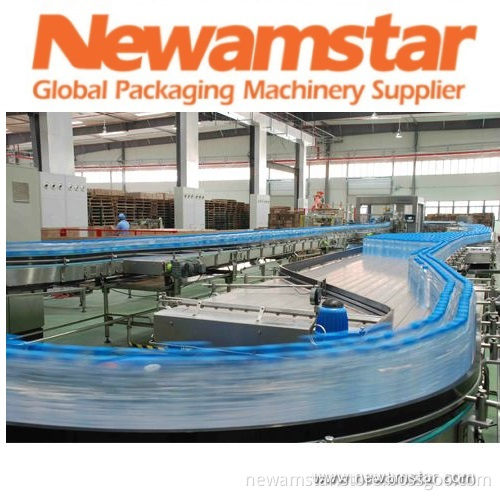

Filled Bottle Conveying System

- Payment Type:

- L/C, T/T

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | China |

|---|---|

| Payment Type: | L/C, T/T |

Product Description

Product Description

Stable conveying, using synchronous chasing control between the conveying belt and engine, making bottles in good condition...

Description:

The working efficiency of the production line is largely decided by the conveying system.

When there is occasional stop on the downstream packaging system (e. G. Label change), the forepart of the production line cannot be effected.

At the same time, the transferring system must connect the equipments in the forepart and rear part well. Newamstar's product is of good rigidity, light weight and good exchanging ability.

It is applied for bottles whose diameter is φ 40~φ 110 mm.

Non-pressure conveying system enables the multi conveying lines become single conveying line during work.

The electric control system adopts PLC to control the running of filled bottle conveying, to realize the automatic speed accelerating or slowing and automatic buffering.

Filled Bottle Conveying System

1, The design of electrical control is advanced and rational, we can design control mode, select electrical control components according to clients layout, to improve the conveying stability.

2, with centralized lubrication system, SUS304 stainless steel water collector, drainage pipeline, etc.

3, Imported sensor checks bottle quantity on conveyor and adjust line speed by inverter.

4, Set the switch according to conveying system layout or customer reasonable requirement, for the conveying stability.

Newamstar Packaging Machinery Co., Ltd.

Description:

The working efficiency of the production line is largely decided by the conveying system.

When there is occasional stop on the downstream packaging system (e. G. Label change), the forepart of the production line cannot be effected.

At the same time, the transferring system must connect the equipments in the forepart and rear part well. Newamstar's product is of good rigidity, light weight and good exchanging ability.

It is applied for bottles whose diameter is φ 40~φ 110 mm.

Non-pressure conveying system enables the multi conveying lines become single conveying line during work.

The electric control system adopts PLC to control the running of filled bottle conveying, to realize the automatic speed accelerating or slowing and automatic buffering.

Filled Bottle Conveying System

1, The design of electrical control is advanced and rational, we can design control mode, select electrical control components according to clients layout, to improve the conveying stability.

2, with centralized lubrication system, SUS304 stainless steel water collector, drainage pipeline, etc.

3, Imported sensor checks bottle quantity on conveyor and adjust line speed by inverter.

4, Set the switch according to conveying system layout or customer reasonable requirement, for the conveying stability.

Newamstar Packaging Machinery Co., Ltd.

Related Keywords

Related Keywords