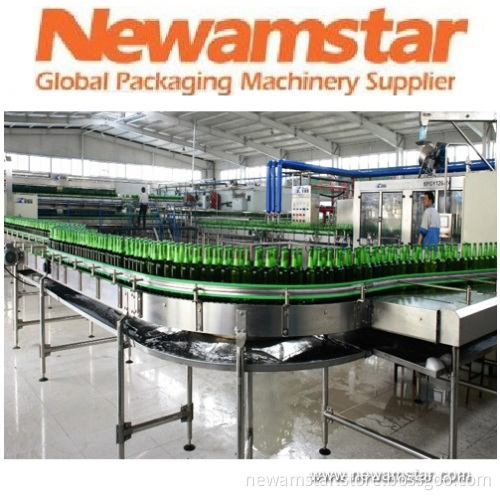

Filled Bottle Conveying Systems

- Payment Type:

- L/C, T/T

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | China |

|---|---|

| Payment Type: | L/C, T/T |

Product Description

Product Description

Filled Bottle Conveying Systems

Modularization design

1, Modularization design has characters of product diversification, simplification, strong parts interchangeability and convenient installation and maintenance, etc. It can make up different conveying way, module units, motors and control way according to different user's requirement, different capacity and bottle model. It has excellent adaptability.

2, Conveying is stable and reliable

The conveyor fence is fixed according to required size. At curve and lane changing place, calculate every lane speed variation according to experiment and theory(increase or reduce by degrees according to geometric progression ), plus synchronous track control with main machine, make bottles do not fall down and block during conveying.

3, Advanced and reasonable electrical control of bottle conveying system

To prevent bottle crushing and explosion during conveying, especially at high speed line, the conveyor adopts catenation control and simple control interoperability.

4, Control components have proximity switch and photoelectric cell, etc.

Control method has diversity. User can require actual control method according to different layout design to achieve purpose of stable conveying.

5, The conveyor structure is compact and noise is little.

6, The conveyor motor drive is not traditional chain wheel drive way, but connecting conveyor main shaft directly. The structure is compact the noise is little.

Convenient to operate

Adopt central control way and common press-button control.

Lubrication way

7, There are two types: Central lubrication and manual lubrication, which has characters of saving time and work.

Main parameters:

Conveyor belt Capacity

(Standard beer bottle): 48000BPH

Fastest speed of single-lane conveyor: Vmax=72m/min

Appicable bottles: Glass bottle

Equipment weight(motors are exclusive)

Average weight of one meter: 30 Kg/m

Water consumption for showering and lubrication: 2~3m3/h

(Bottle Conveying System)

Modularization design

1, Modularization design has characters of product diversification, simplification, strong parts interchangeability and convenient installation and maintenance, etc. It can make up different conveying way, module units, motors and control way according to different user's requirement, different capacity and bottle model. It has excellent adaptability.

2, Conveying is stable and reliable

The conveyor fence is fixed according to required size. At curve and lane changing place, calculate every lane speed variation according to experiment and theory(increase or reduce by degrees according to geometric progression ), plus synchronous track control with main machine, make bottles do not fall down and block during conveying.

3, Advanced and reasonable electrical control of bottle conveying system

To prevent bottle crushing and explosion during conveying, especially at high speed line, the conveyor adopts catenation control and simple control interoperability.

4, Control components have proximity switch and photoelectric cell, etc.

Control method has diversity. User can require actual control method according to different layout design to achieve purpose of stable conveying.

5, The conveyor structure is compact and noise is little.

6, The conveyor motor drive is not traditional chain wheel drive way, but connecting conveyor main shaft directly. The structure is compact the noise is little.

Convenient to operate

Adopt central control way and common press-button control.

Lubrication way

7, There are two types: Central lubrication and manual lubrication, which has characters of saving time and work.

Main parameters:

Conveyor belt Capacity

(Standard beer bottle): 48000BPH

Fastest speed of single-lane conveyor: Vmax=72m/min

Appicable bottles: Glass bottle

Equipment weight(motors are exclusive)

Average weight of one meter: 30 Kg/m

Water consumption for showering and lubrication: 2~3m3/h

(Bottle Conveying System)

Related Keywords

Related Keywords