CSD Filling Machine (DXGF72-72-15)

- Payment Type:

- L/C, T/T

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | China |

|---|---|

| Payment Type: | L/C, T/T |

Product Description

Product Description

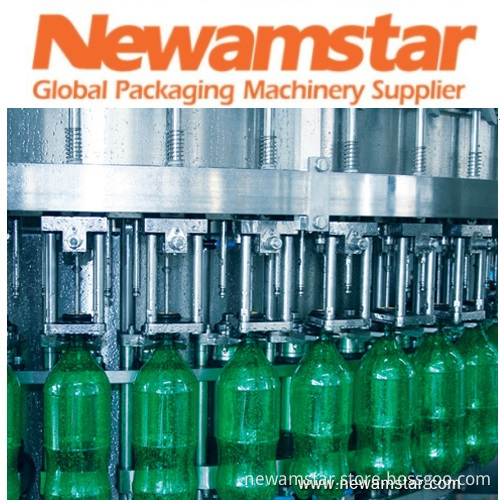

CSD Filling Machine (DXGF72-72-15)

Certificate: ZDHY, CE, ISO9000: 2000

Applied in: Carbonated soft drink filling

Capacity: 22, 000BPH

Structure: Rinser-filler-capping

Gerneral description:

DXGF72-72-15 filling machine is applied in carbonated soft drink filling, like cola, sprite, soda water, etc. Its capacity is 22, 000BPH. Its structure is rinser-filler-capper, 3-in-1 monoblock.

Equipment Structure:

1. Rinsing system: Combined with rotary tray with clamp, water distributing tray, water tank and rinsing pump.

2. Filling system: Combined with hydraulic, filling valve, controlling ring, and elevator-cylinder.

3. Capping system: Combined with capper, cap sorter and cap falling track.

4. Driving system: Combined with main motor and gears.

5. Bottle transmitting system: Combined with air conveyor, steel starwheels and neck supporting carrier plates.

6. Electrical controlling system: This part is frequency inverted, PLC controlled and touch screen operated.

Rinsing machine:

Spraying nozzle is special designed. The cleaning medium could be sprayed in certain angle, which could clean the bottle completely.

Filling machine:

Valve on-off system is hydraulic cylinder controlled. Highly accurate valve could ensure no loss of liquid at the high speed of filling.

Capping machine:

Capping heads are magnetic constant-torque controlled. Broken cap ratio is controlled in 0.2%.

Certificate: ZDHY, CE, ISO9000: 2000

Applied in: Carbonated soft drink filling

Capacity: 22, 000BPH

Structure: Rinser-filler-capping

Gerneral description:

DXGF72-72-15 filling machine is applied in carbonated soft drink filling, like cola, sprite, soda water, etc. Its capacity is 22, 000BPH. Its structure is rinser-filler-capper, 3-in-1 monoblock.

Equipment Structure:

1. Rinsing system: Combined with rotary tray with clamp, water distributing tray, water tank and rinsing pump.

2. Filling system: Combined with hydraulic, filling valve, controlling ring, and elevator-cylinder.

3. Capping system: Combined with capper, cap sorter and cap falling track.

4. Driving system: Combined with main motor and gears.

5. Bottle transmitting system: Combined with air conveyor, steel starwheels and neck supporting carrier plates.

6. Electrical controlling system: This part is frequency inverted, PLC controlled and touch screen operated.

Rinsing machine:

Spraying nozzle is special designed. The cleaning medium could be sprayed in certain angle, which could clean the bottle completely.

Filling machine:

Valve on-off system is hydraulic cylinder controlled. Highly accurate valve could ensure no loss of liquid at the high speed of filling.

Capping machine:

Capping heads are magnetic constant-torque controlled. Broken cap ratio is controlled in 0.2%.

Related Keywords

Related Keywords