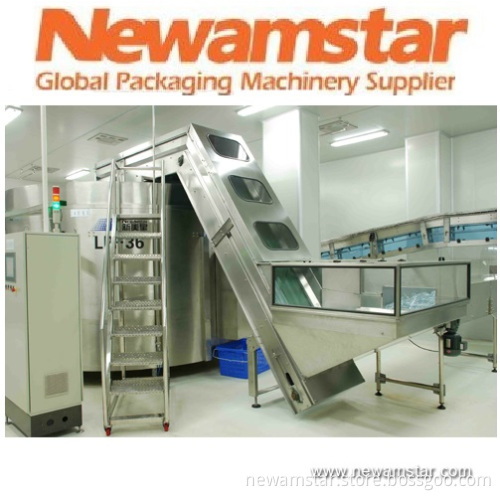

Pet Bottle Unscrambler System

- Payment Type:

- L/C, T/T

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | China |

|---|---|

| Payment Type: | L/C, T/T |

Product Description

Product Description

PET Bottle Unscrambler SystemGeneral descriptionBottle unscrambler is a bottle collocating equipment of internationally advanced level- elevator technology we developed on basis of introduced technology with a consideration of a propensity of domestic beverage filling facilities towards high-speed production. The body machine is barrel shape, with adjustable horses in the bottom of out stainless steel barrel, to adjust the height and level of the machine. An inner and an outer rotary barrel are positioned round the double-line bearings inside the body machine. The outside of inner rotary barrel is equipped with bottle tank, and inside with equivalent elevator. The corresponding bottle distributor is also equipped on the outer barrel. An umbrella-tower is centered in the machine. Bottle Unscrambler Main features: 1. Outer canister, rotary canister and contact parts with bottles are made of S/S SUS304. Frames are welded with carbon steel of fine quality, with anti-rust treated and sprayed of surface. 2. Body of canister is sealed, and kept with slight positive pressure to prevent dust. Top of canister is equipped with removable cover, easy to maintain and clean. 3. Equipped with defective bottle rejection device. No need stop to clean up in running condition. The testing switch in the machine will alarm and stop the machine. Operators can dredge it according to signals. 4. Specially designed bottle tank can apply to bottles of dimensions at small difference, no need to change tank to save investment. For example, if you want to change 600ml with 500ml with same diameter, only 30mm shorter, you need not to change the tank, just do some adjustment. 5. The midst of canister is equipped with exit for mold replacing, easy for dismantlement and clean up of bottle tank. 6. The under of canister is equipped with maintenance exit, easy for operators to contact the bottom of machine. 7. Equipped with manual operators. 8. Prefect safeguard device. 9. Bottle-jam inspector is equipped on feed-out star wheels to safeguard machine. 10. Equipped with oil filling port to lubricate the gears, bearings, and cams.

Related Keywords

Related Keywords