Bottle Blowing Equipment

- Payment Type:

- L/C, T/T, Western Union

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | China |

|---|---|

| Payment Type: | L/C, T/T, Western Union |

Product Description

Product Description

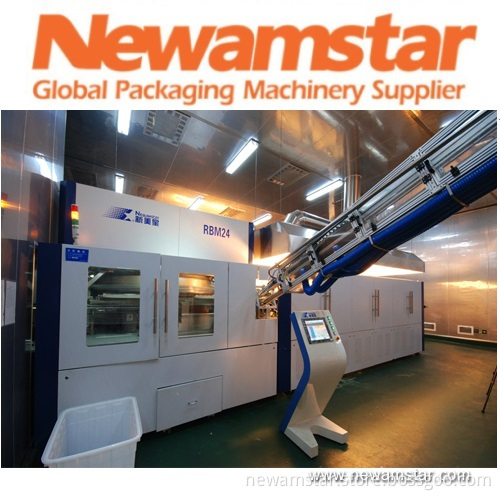

Rotary Blow Molding Machine (RBM)

RBM series rotary blow molding machines apply to the production of PET bottles for water, carbonated soft drinks, hot filling, etc.

Product availability: Subject to actual production plan.

Main characters:

1. Small size and light weight to reduce the cost of your initial investment.

2. High-pressure high-speed diaphragm valve for the secondary blowing system specially

Designed to reduce your cost of operation and maintenance.

3. Design of high-pressure pneumatic to reduce energy consumption up to 40%, significantly lower production costs.

4. Electrical control system for non-contact without delay to protect control of accurate, timely, reliable, durable, reduce downtime, reduce maintenance costs.

5. Good software system, touch-screen operation is simple and easy to learn to adjust, with fault self-diagnosis function, man-machine interface is very friendly and save the training cost.

6. Digital automatic voltage and temperature regulation system ensures that the process is stable and protects the maintenance of low manufacturing costs and reduces investment costs.

Specially designed light box structure, reduce energy consumption up to 50%, significantly

7. Equipped with automatic preform unscrambler and peform loader, to reduce the cost of staff salaries.

RBM series rotary blow molding machines apply to the production of PET bottles for water, carbonated soft drinks, hot filling, etc.

Product availability: Subject to actual production plan.

Main characters:

1. Small size and light weight to reduce the cost of your initial investment.

2. High-pressure high-speed diaphragm valve for the secondary blowing system specially

Designed to reduce your cost of operation and maintenance.

3. Design of high-pressure pneumatic to reduce energy consumption up to 40%, significantly lower production costs.

4. Electrical control system for non-contact without delay to protect control of accurate, timely, reliable, durable, reduce downtime, reduce maintenance costs.

5. Good software system, touch-screen operation is simple and easy to learn to adjust, with fault self-diagnosis function, man-machine interface is very friendly and save the training cost.

6. Digital automatic voltage and temperature regulation system ensures that the process is stable and protects the maintenance of low manufacturing costs and reduces investment costs.

Specially designed light box structure, reduce energy consumption up to 50%, significantly

7. Equipped with automatic preform unscrambler and peform loader, to reduce the cost of staff salaries.

| Technical Description | |

| Mold cavities | 8, 10, 12, 14, 16, 20, 24, 30 |

| Speed | 12, 000-51, 000BPH (500ml) |

| Type of Bottles | PET Bottles of various shapes |

| Bottle Height | 150-340(mm) |

| Bottle Diameter | φ 50-120(mm) |

| Bottle Neck: | 28-38(mm) |

| Product | PET bottles for water, carbonated soft drinks, hot filling and edible oil, etc. |

Related Keywords

Related Keywords