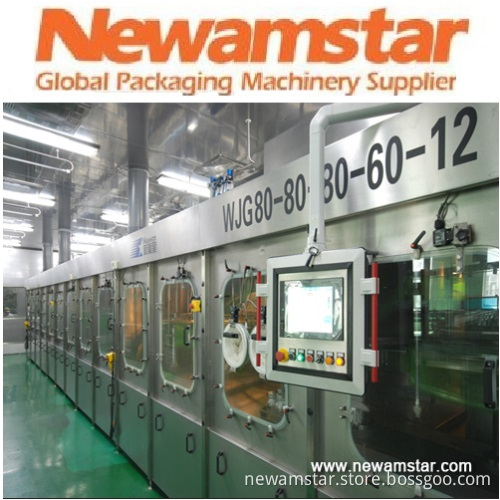

Aseptic Tea Bottling Machine

- Payment Type:

- L/C, T/T

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | China |

|---|---|

| Payment Type: | L/C, T/T |

Product Description

Product Description

Description: Newamstar has the exclusive matured medium and high speed PET aseptic cold filling technology in China. This technology could be applied widely. For both high acid and low acid product, the whole system could ensure the sterilization efficiency to 5D or 6D. Wet sterilization adopts PAA which is used for sterilization of the bottle and cap after being heated. The aseptic zone is realized through isolator. The machine's inside classification clean room is kept through positive pressure. Product capacity: 12000BPH-42000BPHTechnical features: 1, Multi rounds sanitizer spraying and cleaning technology to assure the safety of technics. 2, Mechanical type or electronic pulse type nozzle is of stable performance and water saving. 3, Non-contact filling head avoids cross contamination and ensures the safety of microorganism. 4, Betatron flowmeter gives the exact constant volume. 5, The capping machine is of aseptic type, self lubrication ceramics bearing, equipped with servo-motor. 6, The cap sterilizer is of soaking type or liner spraying type. 7, Automatic inspection, control and parameter record system. All the key points of the production line have been taken aseptic monitoring. The PET aseptic filling system is composed of the following systems: 1, Sanitizer preparation system2, Empty bottle sterilization unit3, Cap sterilization unit4, Sterile material UHT sterilizer5, Sterile material storage and constant pressure system6, Sterile water UHT sterilizer7, Sterile compressed air/nitrogen preparation8, CIP/SIP System9, Aseptic isolation system10, 100 class clean room11, Aseptic zone COP/SOP12, Waste air treatment system13, Liquid sealing system14, Steam generator15, Liquid nitrogen injection system16, Aseptic 5-in-1 filling monoblock17, Whole line automatic control system18, Technical parameter monitor and record system

Related Keywords

Related Keywords