Pet Can Filling Machine for Soda Water and Soft Drink

- Payment Type:

- L/C, T/T, Western Union

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | China Jiangsu |

|---|---|

| Payment Type: | L/C, T/T, Western Union |

Product Description

Product Description

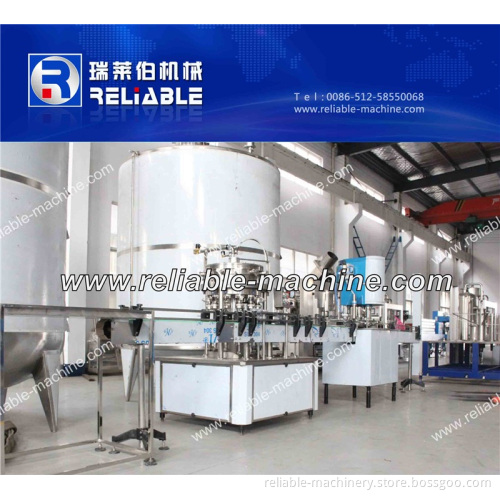

PET Can Filling Machine for Soda Water and Soft Drink

Description

1) Can Rinser

(1). Production Capacity: 1000~2000bottles/hour

Some Questions You May Want Know

Q: What capacity can you offer?

Description

Soda water and soft drink filling machine is composed of bottle washing machine, bottle filling machine and sealing machine, used for PET can fill

Beverage fillling line is the ideal line for food and drink factories.

Capacity is 2000bph, and volume of bottle from 250ml-2000ml.

Features

1. It is applicable for pressure filler and capper of carbonated drinks in beer and drink industry.

2. It is a PET canned beer in the digestion and absorption of advanced foreign and domestic sealing machine on the basis of independent evelopment of the can filling, sealing unit.

3. Filling and sealing is the overall designed, power system by filling sealing system to ensure that both the absolute synchronization and coordination. It adopts the advanced machine, electrical equipment, and pneumatic control technology.

4. It has the characteristics of filling reposefully, high speed, liquid level control, capping reliably, frequency conversion timing, less material loss.

5. It can equip long distance control system according to the customers' request. It is the preferred equipment for the medium beer and beverage plant.

Beverage fillling line is the ideal line for food and drink factories.

Capacity is 2000bph, and volume of bottle from 250ml-2000ml.

Features

1. It is applicable for pressure filler and capper of carbonated drinks in beer and drink industry.

2. It is a PET canned beer in the digestion and absorption of advanced foreign and domestic sealing machine on the basis of independent evelopment of the can filling, sealing unit.

3. Filling and sealing is the overall designed, power system by filling sealing system to ensure that both the absolute synchronization and coordination. It adopts the advanced machine, electrical equipment, and pneumatic control technology.

4. It has the characteristics of filling reposefully, high speed, liquid level control, capping reliably, frequency conversion timing, less material loss.

5. It can equip long distance control system according to the customers' request. It is the preferred equipment for the medium beer and beverage plant.

1) Can Rinser

(1). Production Capacity: 1000~2000bottles/hour

(2). Speed of main bearing 1.4circlel/minute

(3). Number of rinsing bottle 24 heads

(4). Specification of rinsing bottle 250ml-750ml (Can bottle)

(5). Specification of water entry pipe G1/2"

(6). Speed reducer WD -110X 20:1 1.5KW

(7). the power of motor 1.5 KW

(8). Overall dimension 1130X960X1370mm

(9). Total weight 600Kg

2)Can Filler

Filling machine for soda water & soft drink

(1), pressure instead of bottle: 0.15-0.35Mpa

(2), maximum temperature inside bottle :5ºC

(3), Main electrical machinery: type: YTC132-4B, power: 1.5KW rotational speed: 1250-125 r/m,

(4), Maximum production capacity: 1000~2000b/h

(5),External dimension:1200×1200×1200mm

(6), Net weight: 1500kg

3)Can Capper

1. Overall size: 930*700*1850

2. Weight: 500kg

3. Motor power: 0.75kw 1390r/min

4. Production capacity: 1000~2000BPH

5. specification of can: φ50-67, H90-200, cans beyond this size can be designed specially.

Some Questions You May Want Know

Q: What capacity can you offer?

A: Refer to the capacy diagram above.

Q: What is the type of your company?

A: We are industrial manufacturer, which locates in Zhangjiagang city.

Q:All of your products are made by yourself or compacted via purchasing the others?

A: We have an independent technical team who specialize on making the beverage filling machines, all of them are made by ourselves.

Q: Do you have any technical supports with your PET Can Filling Machine ?

A:We have a professional team of engineers who owned many installation, debug and training experiences abroad, are available to service machinery overseas.

Related Keywords

Related Keywords

You May Also Like

You May Also Like