CE/ISO/SGS Granulator Machine for PE PP Film

- Payment Type:

- L/C, T/T, Western Union

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | China |

|---|---|

| Payment Type: | L/C, T/T, Western Union |

Product Description

Product Description

Product Description

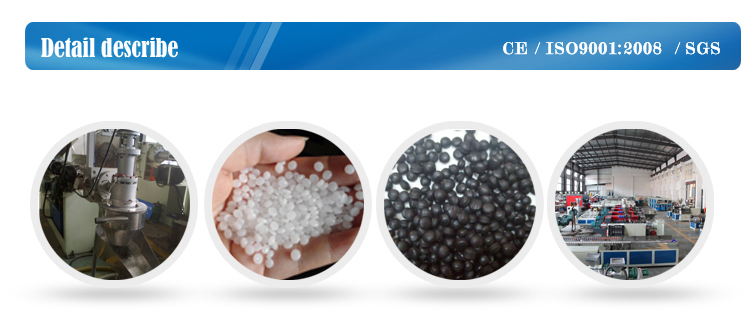

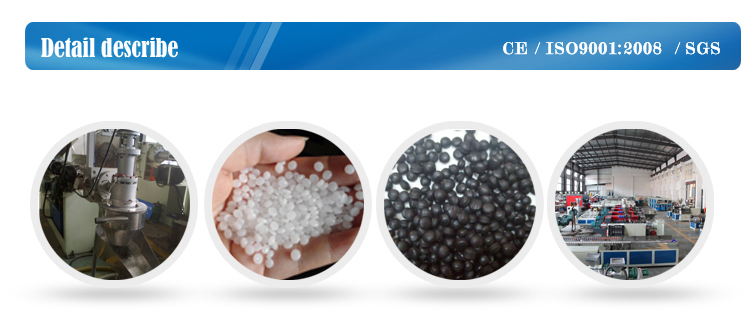

PP PE Film Plastic Compactor Pelletizing Line

Plastic Granulator machine Applications:

Applicable plastic materials: PE, HDP E, LDPE, PP, BOPP, etc

Applicable plastic materials: PE, HDP E, LDPE, PP, BOPP, etc

Material shapes: film, bag, (PE, PP) regrind

Material types: rolls, loose, bundled

Material comes from offcut, industry defective film, washed film and printed film.

Note: depending on different material properties, various downstream equipments are needed.

Advantages:

1. Material will be cut, pre-heated, pre-dried, mixed and compacted in the cutter Compactor machine

2. Highly efficient with good performance, Less power consumption, Highly automatic

3. Special designed for recycling PE, PP films and regrind in one machine

4. CE Certificate

5. Long service life

6. Customized

7. Support installation and operation training at Buyer's plant

Remark: films and regrind can be recycled in one machine, together or separately

Plastic Granulator machine Production Process:

Feeding materials onto the Belt Conveyor materials being pre-heated, cut and compacted in the Cutter Compactor /Agglomerating machine being squeezed evenly in the Extruder coming out from the machine head after venting and filtering system Hydraulic screen changer being cut by Water ring pelletizing sytem being dried by Dewatering system being trasnferred into the Silo the End.

Material types: rolls, loose, bundled

Material comes from offcut, industry defective film, washed film and printed film.

Note: depending on different material properties, various downstream equipments are needed.

Advantages:

1. Material will be cut, pre-heated, pre-dried, mixed and compacted in the cutter Compactor machine

2. Highly efficient with good performance, Less power consumption, Highly automatic

3. Special designed for recycling PE, PP films and regrind in one machine

4. CE Certificate

5. Long service life

6. Customized

7. Support installation and operation training at Buyer's plant

Remark: films and regrind can be recycled in one machine, together or separately

Plastic Granulator machine Production Process:

Feeding materials onto the Belt Conveyor materials being pre-heated, cut and compacted in the Cutter Compactor /Agglomerating machine being squeezed evenly in the Extruder coming out from the machine head after venting and filtering system Hydraulic screen changer being cut by Water ring pelletizing sytem being dried by Dewatering system being trasnferred into the Silo the End.

| Model | Screw diameter(mm) | L/D | Output (kg/h) |

| BM-C85 | 85 | 25-33 | 120-180 |

| BM-C100 | 100 | 25-42 | 200-350 |

| BM-C130 | 130 | 25-36 | 400-550 |

| BM-C160 | 160 | 25-33 | 600-800 |

| BM-C180 | 180 | 25-33 | 800-1200 |

| Main Technical Parameters | ||||

| MODEL | L/D RATIO | PELLETIZING WAY | APPLICABLE MATERIALS | OUTPUT |

| 120/130 | 16-40/1 | Water cool strand pelletizer or Water ring die-face hot pelletizer | PET,PE,HDPE bottle, PE PP film, ABS PA etc | 200-300 |

| 130/150 | 300-400 | |||

| 150/180 | 450-550 | |||

Related Keywords

Related Keywords