Green Field Plasic Film Complete Washing and Drying Production Line

- Payment Type:

- L/C, T/T, Western Union

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | China |

|---|---|

| Payment Type: | L/C, T/T, Western Union |

Product Description

Product Description

Product Description

Green field Plasic film complete washing and drying production line

Waste plastic machine is used to Recycling Washing the waste PE/PP Film, HDPE milk bottles, Rigid PE/PP containers, buckets and so on. Its a automatic line including the material feeding conveyor Belt, Wet grinder/crusher machine, Frication Washing machine, Floating washing tank, Dewatering dryer machine, Hot air drying system and collecting system. Also we have film squeezing machine in the end to drying the material optional choose;

We can produce the Line according to your requirement based on our suggestion. We have different components and capacity line for your choose;

Raw Material(plastic machine)

Waste Plastic, HDPE Bottles, PE/PP Film

Capacity Model(plastic machine)

According to different plastic material

General Machine List Components(plastic machine):

For PE/PP bottle, film and so on

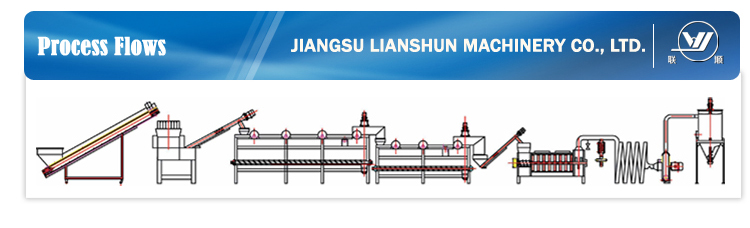

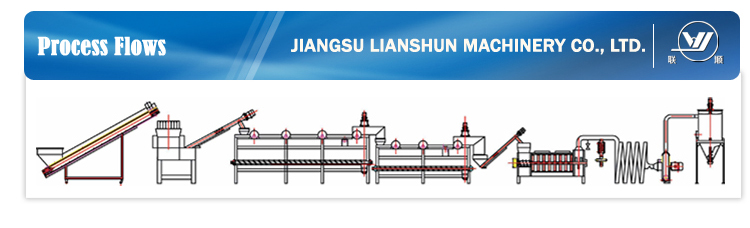

Feeding Conveyor---Plastic Crusher machine---Flakes Floating washing tank---Frication washing system---dewatering machinery ---hot air drying system and the Packing system

Machine model(plastic machine):

· ME series

Machine Features(plastic machine):

· PP PE Recycling Line

Function description(plastic machine):

· PP PE Recycling Line

Quality Control(plastic machine):

· We have technical, engineer team design the sample machinery before enter into market

· Production QC team ensure the machine manufacturing quality

· We will running every machine after finished before shipment

· Optional choose by client running the machinery by material

Service System(plastic machine):

· Pre-sale: We given client the details technician offer, sign the sales contract etc.

· In-sales: We supply the details layout, installation instruction, technician support for the clients;

· After sales: We arrange engineer to install the machinery and training the workers for client;

· We have 24hours team to solve the after sales problem;

· We have free spare parts with the machine;

· We supply long term spare parts for every customer

· We always up date the new technology to every customer

Photos of machine(plastic machine):

Waste plastic machine is used to Recycling Washing the waste PE/PP Film, HDPE milk bottles, Rigid PE/PP containers, buckets and so on. Its a automatic line including the material feeding conveyor Belt, Wet grinder/crusher machine, Frication Washing machine, Floating washing tank, Dewatering dryer machine, Hot air drying system and collecting system. Also we have film squeezing machine in the end to drying the material optional choose;

We can produce the Line according to your requirement based on our suggestion. We have different components and capacity line for your choose;

Raw Material(plastic machine)

Waste Plastic, HDPE Bottles, PE/PP Film

Capacity Model(plastic machine)

According to different plastic material

General Machine List Components(plastic machine):

For PE/PP bottle, film and so on

Feeding Conveyor---Plastic Crusher machine---Flakes Floating washing tank---Frication washing system---dewatering machinery ---hot air drying system and the Packing system

Machine model(plastic machine):

· ME series

Machine Features(plastic machine):

· PP PE Recycling Line

Function description(plastic machine):

· PP PE Recycling Line

Quality Control(plastic machine):

· We have technical, engineer team design the sample machinery before enter into market

· Production QC team ensure the machine manufacturing quality

· We will running every machine after finished before shipment

· Optional choose by client running the machinery by material

Service System(plastic machine):

· Pre-sale: We given client the details technician offer, sign the sales contract etc.

· In-sales: We supply the details layout, installation instruction, technician support for the clients;

· After sales: We arrange engineer to install the machinery and training the workers for client;

· We have 24hours team to solve the after sales problem;

· We have free spare parts with the machine;

· We supply long term spare parts for every customer

· We always up date the new technology to every customer

Photos of machine(plastic machine):

|

Number |

Description |

Technical parameters |

Quantity |

|

1 |

Belt Conveyor |

1.Length: 4000mm 2. Width: 600mm 3. Material: Rubber 4. Conveying Capacity: 300Kg /h 5. Motor: 1.5KW |

One set |

|

2 |

Crusher with Water |

1. Model: PC700 2. Crush Capacity: 200Kg /h 3. Knife Material: Cr12MoV 4. Motor Power: 22KW 5. Feeder Throat Dimension: 700× 450mm 6. Knife Gyration Diameter: Φ 360mm |

One set |

|

5 |

Screw Conveyer |

1. Motor Power: 1.5KW 2. Conveying Capacity: ≥ 200kg /h 3. With Water-drainage Function. 4. Process Material: Stainless Steel |

One set |

|

3 |

High speed friction washing machine |

1) Motor power: 15 KW 2) Filtering method: Stainless Steel mesh 3) Process material: Stainless Steel 4) Principal axis diameter: 300mm 5) Principal axis rotate speed: 750r/min 6) Spraying mouth on top: 2 fleets, 8 mouths 7) Principal axis is through dynamic & static balance correction. 8) The equipment is with the material-feeding function. |

One set |

|

4 |

Washing tank |

1. Stir Motor Power: 3KW 2. Effective Washing Length: 6000mm 3. Tank Material: Stainless Steel 4. Residue Exclude Method: By Screw |

One set |

|

5 |

Screw Conveyer |

1. Motor Power: 1.5KW 2. Conveying Capacity: ≥ 200kg /h 3. With Water-drainage Function. 4. Process Material: Stainless Steel |

One set |

|

6 |

Film Dewatering Machine |

1. Motor Power: 37KW 2. Rotary Speed: 1500rpm 3. Process Material: Stainless Steel 4. Main Shaft: Through dynamic and static balance treatment. 5. Water -drainage Method: Downwards. |

One set |

|

7 |

Drying System |

1. Fan Motor Power: 5.5KW 2.Heating Power:28KW,Electricity Heating Pipe, total 3 Groups 3. Pipe Tract Material: Stainless Steel 4. Pipe Tract Diameter: Φ 159mm 5. Pipe Tract Type: "U" Type |

One set |

|

8 |

Material Store System/ hopper |

1. Cubage: 1 M ³ 2. Process Material: Stainless Steel 3. Material Lay-off Control: Plate Valve |

One set |

| 9 | Electricity Control |

1. Contactor is brand"siemens" |

One set |

Related Keywords

Related Keywords