CE/ISO/SGS Indoor PVC Application Plastic Decorated Profile Produtcion Line

- Payment Type:

- L/C, T/T

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | China |

|---|---|

| Payment Type: | L/C, T/T |

Product Description

Product Description

Product Description

wood plastic composite wpc production line

Description

With special designed screw ,barrel.moule and producing process ,this line can produce PE PP and wood powder profile.This is a new kind of environmental freindly building material.Mixing the plastic ,wood powder ,foam agent and other additives.After high temperature and high pressure extrusion ,the products can be used for pallets ,packing plates ,windows and door frames ,decoration panels and etc .

The production line with the following feathers:

1)This technology is suitable to produce WPC products at high value with variety of plastic and nature fiber,and the material is 90% of waste plastic and waste natural fiber

2)With scientific and reasonable technology,the machine has high efficiency and runs stably

3)The parallel twin screw extruder is used to mix the wood and plastic,and get good homogeneous melt.

4)This is one step WPC extrusion technology,which saves energy

5)This production line can produce wpc products of different specifications only to change mold.

6)Imported PLC automatic control.

Complete process:

Milling → Mixing → Extruding → Mold → Product → Calibrating → Cutting off→ Embossing or polishing→ Final product

Pre-sale

We provide presales service in various forms, for example, making investment budget,manufacturing

planning, etc. so that customers make a reasonable plan with less cost.

Investment budgeting: We provide services of product profit analysis, recommendation of machine and auxiliary equipment and relevant budgeting, human resources allocation and budgeting.

Plant Planning: We provide the mounting dimension of the equipment base,design of equipment layout, workshop ventilation, water transmission etc

Offer information of peripherals

In-sale :

Detailed design of lay-out that is the position of the procession

Technological information of provided products

Schedule about design,manufacturing and installation

Working & Producing progression

Training course for the technician so that the installation is safe and standard

After-sale :

For customers buying our products, we provide them free training so that they can use and maintain the machine independently.

We will answer customer's question on technology in time. If needed, we will offer on-site guidance and assistance.

We can provide free technical guidance if customers need new equipment, add or rebuild equipment.

| Model | SJZ180 | SJZ240 | SJZ300 |

| Max pipoe diam(mm) | 180 | 240 | 300 |

| Auxiliary total power(kw) | 15 | 24 | 30 |

| Cooling water capacity(m3/h) | 5 | 7 | 7 |

| Compressed air pressure(Mpa) | 0.6 | 0.6 | 0.6 |

| Item | Name | specification | quantity |

| 1 | Powder feeder | ZJF300 | 1set |

| 2 | Conical twin-screw extruder | SJSZ-51/105 | 1set |

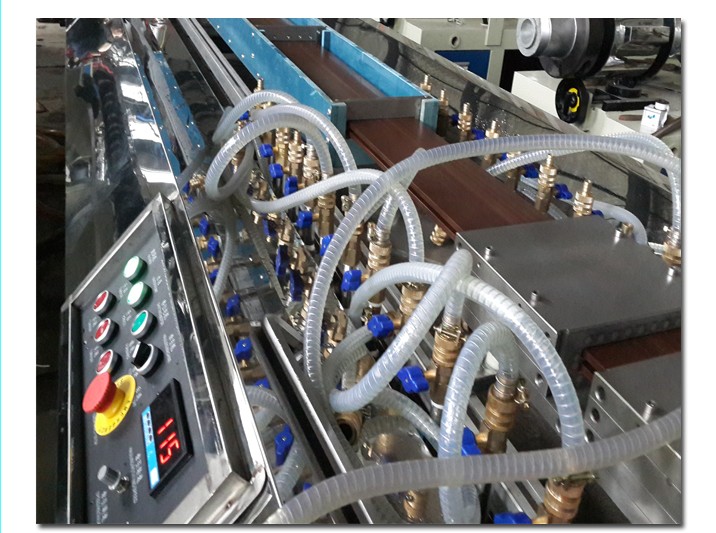

| 3 | Vacuum calibration table | ZK-4000 | 1set |

| 4 | Cutting machine | QG-120 | 1set |

| 5 | stacker | FL-120 | 1set |

| 6 | Mould | ||

Related Keywords

Related Keywords

You May Also Like

You May Also Like