Full Automatic Complete PVC Pipe Making Machine

- Payment Type:

- L/C, T/T

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | China |

|---|---|

| Payment Type: | L/C, T/T |

Product Description

Product Description

Product Description

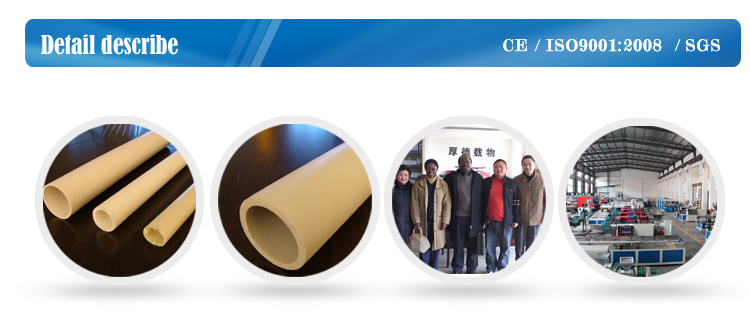

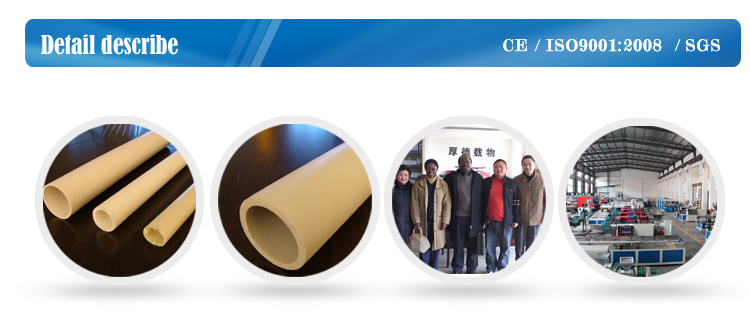

CE/ISO/SGS High Quality prodution line for PVC pipe make (SJSZ)

PVC pipe production line/PVC pipe extrusion line is mainly used to produce PVC pipes with various diameters and wall thickness in the aspects of agricultural irrigation, water supply, drainage and wire conduit etc.

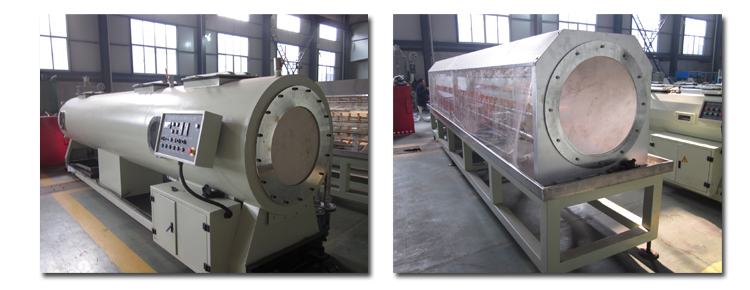

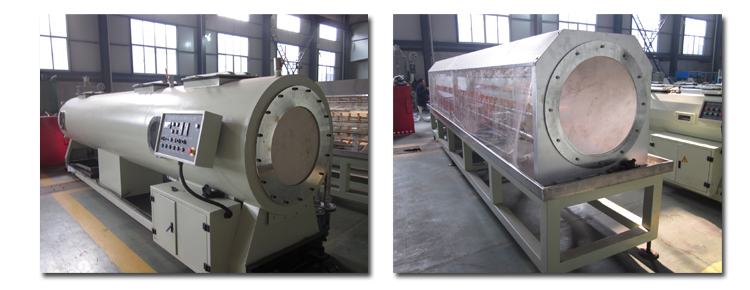

The main components of PVC pipe production line including:

1. Twin-screw extruder,

2. Mould,

3. Vacuum calibration and cooling tank,

4. Hualing off machine(2-pedrails, 3-pedrails, 4-pedrails, 6-pedrials, 8- pedrials)

5. Printer(ink jet printer, imitating ink jet printer)

6. Cutter(lift-up cutter, planetary cutter)

7. Stack bracket

Auxiliary machines of PVC pipe production line:

1. Hot and cooling mixer

2. Socketing machine

3. PVC crusher and pulverizer

4. Water chiller and air compressor etc,

Advantages:

1. All main electric elements are world famous brand, like Siemens, FUJI, ABB and Schneider

2. Superior quality screw and barrel which are designed with CAD and processed by advanced CNC lathe according different formula which can make sure scientific inner structure and best plasticizing effect

3. Equipped with best gear box in China which can make sure long service life.

4. Optimized design to make lower electric consumption and increase efficiency

5. Mature technology, rich experience enables us to lower the production cost to give you good price.

PVC pipe production line/PVC pipe extrusion line is mainly used to produce PVC pipes with various diameters and wall thickness in the aspects of agricultural irrigation, water supply, drainage and wire conduit etc.

The main components of PVC pipe production line including:

1. Twin-screw extruder,

2. Mould,

3. Vacuum calibration and cooling tank,

4. Hualing off machine(2-pedrails, 3-pedrails, 4-pedrails, 6-pedrials, 8- pedrials)

5. Printer(ink jet printer, imitating ink jet printer)

6. Cutter(lift-up cutter, planetary cutter)

7. Stack bracket

Auxiliary machines of PVC pipe production line:

1. Hot and cooling mixer

2. Socketing machine

3. PVC crusher and pulverizer

4. Water chiller and air compressor etc,

Advantages:

1. All main electric elements are world famous brand, like Siemens, FUJI, ABB and Schneider

2. Superior quality screw and barrel which are designed with CAD and processed by advanced CNC lathe according different formula which can make sure scientific inner structure and best plasticizing effect

3. Equipped with best gear box in China which can make sure long service life.

4. Optimized design to make lower electric consumption and increase efficiency

5. Mature technology, rich experience enables us to lower the production cost to give you good price.

| Pipe Range | 16-63mm (single) | 16-63mm(dual) | 75-160mm | 110-315mm | 315-630mm |

| Extruder type | SJZ51/105 | SJZ65/132 | SJZ65/132 | SJZ80/156 | SJZ92/188 |

| Motor power | 18.5KW | 37KW | 37KW | 55KW | 110KW |

| Capacity | 120kg/hour | 250kg/hour | 250kg/hour | 360kg/hour | 800kg/hour |

| Lineal speed | 12m/min | 10m/min | 6m/min | 3m/min | 1.2m/min |

Related Keywords

Related Keywords

You May Also Like

You May Also Like