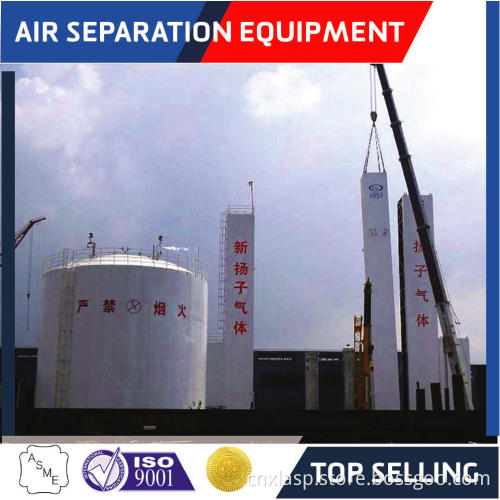

Kdonar-1500y-1250g-740y/75y Air Separation Plant

- Payment Type:

- L/C, T/T

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Suzhou, China |

|---|---|

| Payment Type: | L/C, T/T |

Product Description

Product Description

Less investment cost than medium-pressure cycle. Generally, compressors used for normal process of liquid plant are designed and manufactured specially, but our patent process adopts standard centrifugal compressor, so investment is reduced much. As we know, investment of compressor takes a large part of the whole plant.

Multi-stage refrigeration process which consists of waste nitrogen pre-cooling, cold refrigerator, double stage expansion, features higher efficiency, lower power consumption, and shorter startup time.

Fractionation column of liquid plant up to 200TPD could be assembled into sections before delivery. Compared with loose equipment delivery and site assembly, this type of column could save much installation time and cost, and improves the reliability of the whole plant.

Hydrogen-free rectified argon system is available on 35TPD liquid oxygen plant or larger, with fractionation column lower than 35m.

Product liquid is delivered under pressure directly into storage tank with large sub-cooling degree, which reduces vaporization loss during storage and transfer.

Due to pantent process and exclusive know-how, our liquid plants take a very large market share.

Original Atlas Copco centrifugal compressor, original Bitzer refrigerating compressor, original Siemens PLC.

Multi-products as per customer's requirement, including LO2, LN2, LAr, GO2, GN2. Very convenient to produce GN2( pressure higher than 8 barg) as by-product.

Multi-stage refrigeration process which consists of waste nitrogen pre-cooling, cold refrigerator, double stage expansion, features higher efficiency, lower power consumption, and shorter startup time.

Fractionation column of liquid plant up to 200TPD could be assembled into sections before delivery. Compared with loose equipment delivery and site assembly, this type of column could save much installation time and cost, and improves the reliability of the whole plant.

Hydrogen-free rectified argon system is available on 35TPD liquid oxygen plant or larger, with fractionation column lower than 35m.

Product liquid is delivered under pressure directly into storage tank with large sub-cooling degree, which reduces vaporization loss during storage and transfer.

Due to pantent process and exclusive know-how, our liquid plants take a very large market share.

Original Atlas Copco centrifugal compressor, original Bitzer refrigerating compressor, original Siemens PLC.

Multi-products as per customer's requirement, including LO2, LN2, LAr, GO2, GN2. Very convenient to produce GN2( pressure higher than 8 barg) as by-product.

Related Keywords

Related Keywords