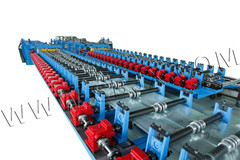

High Speed Track Cutting Roofing Roll Forming Machine

- Payment Type:

- L/C, T/T, Money Gram, Western Union

Quantity:

Your message must be between 20 to 2000 characters

Contact NowBasic Info

Basic Info

| Place of Origin: | Jiangsu, China |

|---|---|

| Payment Type: | L/C, T/T, Money Gram, Western Union |

Product Description

Product Description

Servo Feeding

Machine adopt servo feeding to get high speed

Servo power: 4KW

Servo brand: Yaskawa

Forming Section

Material of the profile: GI or color steel :

Thickness range: 1mm

Main motor power:15kw, AC motor, motor inside of main machine

Machine Voltage, Frequency, Phase: 380 V, 50 Hz, 3Phase

Roll station: about 20 stations (according the final design)

Roller material:ASTM1045 chrome plated surface with chrome,CNC

Shaft diameter: ¢85mm material: SAE1045 with quenching and tempering

Machine roll forming speed: not less than40m/min

Transmission: gear box

Roll former has leveling bolts in the base for adjust the leveling

Machine base frame adopt H beam welding steel

In the main roll forming machine have 2 buttons for urgency stop if happen any malfunction.

Machine adopt new iron cast

Hydraulic cutting

Cutting after forming: Cut the sheet after roll forming to required length, hydraulic track cutting

Material of blade:Cr12, 58-62 HRC hardness

Cutting power by hydraulic 5.5KW energy tank

Working pressure: 25Mpa adjustable

Length measuring: Automatic encoder length measuring, brand: Omron

The cutting sequence is also contained and controlled by the same PLC program

Tolerance of length: +/- 1.5mm for each piece end product

Machine adopt servo feeding to get high speed

Servo power: 4KW

Servo brand: Yaskawa

Forming Section

Material of the profile: GI or color steel :

Thickness range: 1mm

Main motor power:15kw, AC motor, motor inside of main machine

Machine Voltage, Frequency, Phase: 380 V, 50 Hz, 3Phase

Roll station: about 20 stations (according the final design)

Roller material:ASTM1045 chrome plated surface with chrome,CNC

Shaft diameter: ¢85mm material: SAE1045 with quenching and tempering

Machine roll forming speed: not less than40m/min

Transmission: gear box

Roll former has leveling bolts in the base for adjust the leveling

Machine base frame adopt H beam welding steel

In the main roll forming machine have 2 buttons for urgency stop if happen any malfunction.

Machine adopt new iron cast

Hydraulic cutting

Cutting after forming: Cut the sheet after roll forming to required length, hydraulic track cutting

Material of blade:Cr12, 58-62 HRC hardness

Cutting power by hydraulic 5.5KW energy tank

Working pressure: 25Mpa adjustable

Length measuring: Automatic encoder length measuring, brand: Omron

The cutting sequence is also contained and controlled by the same PLC program

Tolerance of length: +/- 1.5mm for each piece end product

Related Keywords

Related Keywords