DIN2391 Precision Seamless Carbon Steel Tube E355 , OD 10mm

- Min. Order:

- 1

- Min. Order:

- 1

- Delivery Time:

- 30 Days

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | CHINA |

|---|

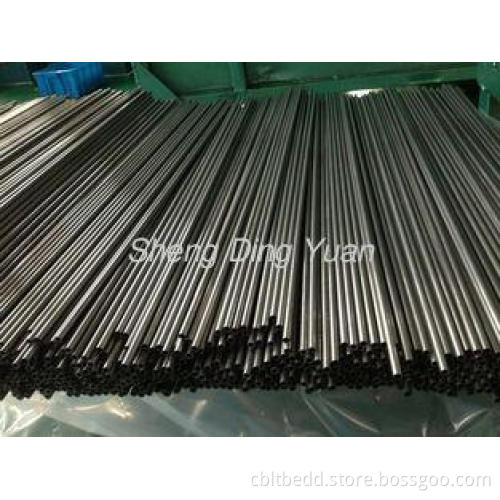

DIN2391 Precision Seamless Carbon Steel Tube E355 , OD 10mm TH 1.5mm

Tube dimensions for E355 precision seamless carbon tube

- OD:4-60mm,WT:0.5-60mm

- Standard:DIN2391/C,EN10305-4

-

Material:st35,st37,st37.4,st45,st52,st52.4,E235,E355

- Delivery Condition:BK,BKW,BKS,NBK,GBK(Bright annealing without oxidization)

- Length:5800mm,6000mm.

- Package:Bundles or wooden cases.

- Surface Anti-rust:Both outside and internal tube surface flushing with anti-rust oil.

- Surface quality:very smooth and bright without oxide scale,pock,strach,crack and other defects..

- Surface Cleaness:clean without iron scrap,dust,better for hydraulic system life.

- Mechanical Properties:Better extending rate and strength property.

- Test:Tensile Strength Test,Hardness Test,Chemical Compositon Test

- Material: Precision tubes are made from carbon steel from quality Bao Steel,XingCheng Steel,and HuaiSteel.

Tolerance Table Of Steel Tube

|

NAME |

SCOPE(mm) |

GB (mm) |

DIN (mm) |

Enterprise control(mm) |

Special high-precision(mm) |

|

Out Diameter |

4-30 |

±0.1 |

±0.08 |

±0.05 |

±0.03 |

|

31-40 |

±0.15 |

±0.15 |

±0.05 |

±0.03 |

|

|

41-50 |

±0.20 |

±0.20 |

±0.08 |

±0.03 |

|

|

51-60 |

±0.25 |

±0.25 |

±0.08 |

±0.03 |

|

|

Wall thickness |

0.5-7 |

±10%,Min±0.12 |

±10% |

±10%,Min±0.05 |

±10%,Min±0.03 |

Steel grades for E355 precision seamless carbon tube

|

Standard |

Material |

|

EN10305-1 |

E215, E235, E255, E355,C45E, 30GrMo |

|

DIN2391 |

ST35, ST45, ST52, ST37.4 |

|

DIN1630 |

ST37.4,ST44.4,ST52.4 |

|

BS6323/4 |

CFS3,CFS4,CFS5,CFS8 |

|

ASTMA519 |

SAE1010,SAE1020,SAE1045 |

|

JISG3445 |

STKM11A,STKM13A |

|

SAEJ524 |

SAE1010

|

Delivery condition and heat treatment processing

|

Delivery Condition |

Heat treatment process |

|

+C |

Cold drawn/hard.After the last cold forming,no heat treatment. |

|

+LC |

Cold drawn/soft.After the last heat treatment follows the cold drawing there is a light finishing pass.

|

|

+SR |

Cold drawn and stress relieved annealed. After the final cold drawing process the tubes are stress relieved annealed in a controlled atmosphere. |

|

+A |

After the final cold drawing process the tubes are stress relieved annealed in a controlled atmosphere. |

|

+N |

Normalized. After the last cold drawing process the tubes are annealed in a controlled atmosphere. |

Manufacturing:

Synopsis of Process Routing: Quality Carbon steel — Cold Drawn — Heat Treatment Without Oxidization (NBK Status) — Nondestructive Testing— Flushing The Internal Hole With Special Equipment Under The High Pressure —Dealing With Antirust Oil On Surface — Plastic Capping On Both Ends.

Applications:

Precision tubes are used in hydraulic system,automobile,mechanical parts and in the occasion where the high precision,brightness,cleanness and mechanical properties of the tube are required.

Competitive Advantage:

- Certificate we awarded:TS 16949

- Our typical customer: Continential Contitech,Benteler.

- We have passed BMW’S review.

- We have been cooperating with many auto parts manufacture,our tubes are widely used in BMW,Volkswagen,and other brands.

- 400 tons precision steel tubes stock capacity,this make our delivery time short and timely.

Production Line:

Production Equipment:

Packing and loading:

Laboratory Testing:

Our Customer:

Certificate Approved: