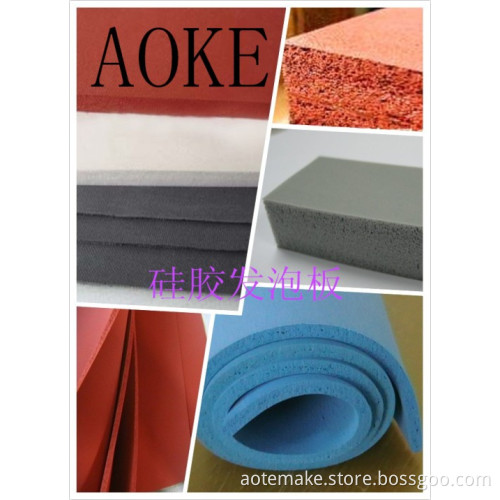

Closed-cell silicone foam board

- Payment Type:

- T/T, L/C, D/A, D/P, Western Union

- Incoterm:

- FOB

- Min. Order:

- 1 Piece/Pieces

- Min. Order:

- 1 Piece/Pieces

- Delivery Time:

- 7 Days

- Transportation:

- Ocean, Land, Air

Your message must be between 20 to 2000 characters

Contact Now| Place of Origin: | China |

|---|---|

| Productivity: | 1000000000 |

| Supply Ability: | 10000000000000 |

| Payment Type: | T/T,L/C,D/A,D/P,Western Union |

| Incoterm: | FOB |

| Certificate: | FDA |

| Transportation: | Ocean,Land,Air |

Silicone foam/sponge sheet is an ideal material for sealing, cushioning, vibration isolation and adiabatic. Their features of resistance to environmental extremes, mechanical resilience and safety make them ideally suited in PCB circuit board lamination, electric auto parts, transportation equipment, communications and electrical equipment, electronic products and components, industrial machinery and electrical critical. AOKE silicone foam can also provide excellent flame resistance and fire protection. Suzhou AOKE silicone sponge is the best choise of the hybrid battery separator pad and solar panels, as well as cushioning materials such as high-speed rail applications requiring high reliability.

AOKE silicone foam with multi-purpose, multi-hardness, a variety of colors and flame retardant grade, has the chracteristic of lightweight, heat resistance, better sealing ability than traditional sponge rubber and irreplaceable superior electrical performance.

1.Color: black, gray and red, white

2.The thickness can be obtained: 0.5-55 mm

3.Typical density: 0.35-0.85g/cm3

4. Hardness 8-35Shore C

5. Level: UL V0 and HF1 and practices

6. Temperature range: -40-240C

7. Dielectric properties (resistance, voltage): > 10KV

8. Thermal conductivity: 0.2-0.3 W / M-K

9. Follow-up processing methods: cutting, punching, composite glass fiber textile fabrics, stamping sealing materials

10. Surface: can be smooth, with patterns, or with self-adhesive double-sided adhesive tape

11. Size: 500mm * 2000mm and 1000mm * 20000mm

12. Others: properties equivalent: Rogers BISCO ® Silicone HT-800 / BF-1000/BF-2000 etc.

13. Manufacturer: Suzhou AOKE Rubber Technology Ltd

Related Keywords